I think I'm set on:

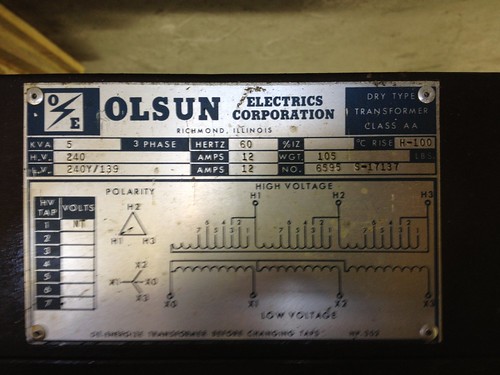

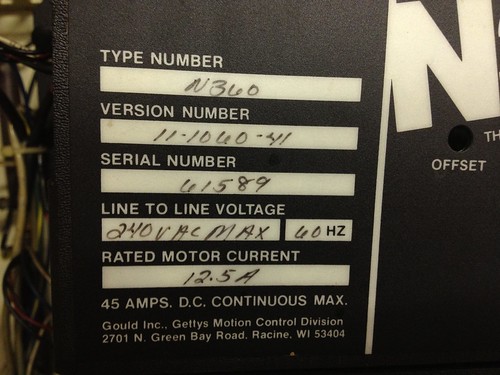

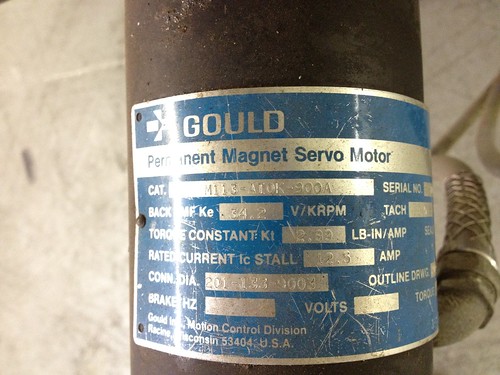

Existing servo motors 86V 12.5A

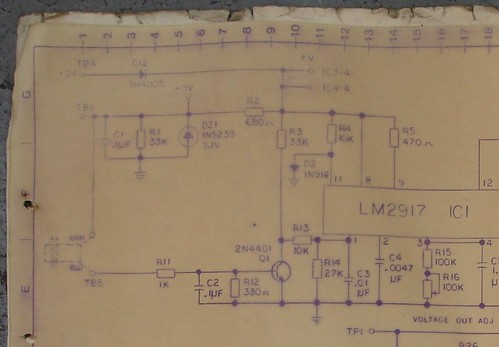

Existing encoders (if they work) 5V 500p/rev

Power supply 1.5kW unless I can find 2kW

Antek - PS-15N77

Options:

#1 Pico systems:

EMC2

Universal PWM Servo Controller (4 axis) $250

Pico Systems Universal PWM Servo Controller

PWM Servo Amp $125 x 3

Pico Systems PWM Servo Amplifier

Parallel port ?

Spindle Digital to Analog (DAC) speed control $50

#2 Mesa:

Mesa Electronics

EMC2

5i25 PCI card $89

7i76 Step/dir daughtercard 5 axis step/dir + i/o + spindle control $119

Gecko 320 $115 x 3

#3 Mesa:

EMC2

same as above but with 7i77 analog servo interface instead of step/dir

analog drives???

#4 Dynomotion:

Dynomotion | Motion Control Boards

Dynomotion software: KMotionCNC

KFLOP $250 USB

SnapAmp1000 $400 4 brushed servos, 80V, 8A cont., 15A peak + 14 i/o

Kanalog $250 a bunch of i/o

I'm a little wary of the software because I don't know anything about it.

I like the idea of the Mesa 5i25 being a purpose built PCI card rather than a repurposed printer port.

I'd really like peoples comments on EMC vs Dynomotion and also general comments and guidance. Thank you.

Reply with Quote

Reply with Quote