Hello Pete,

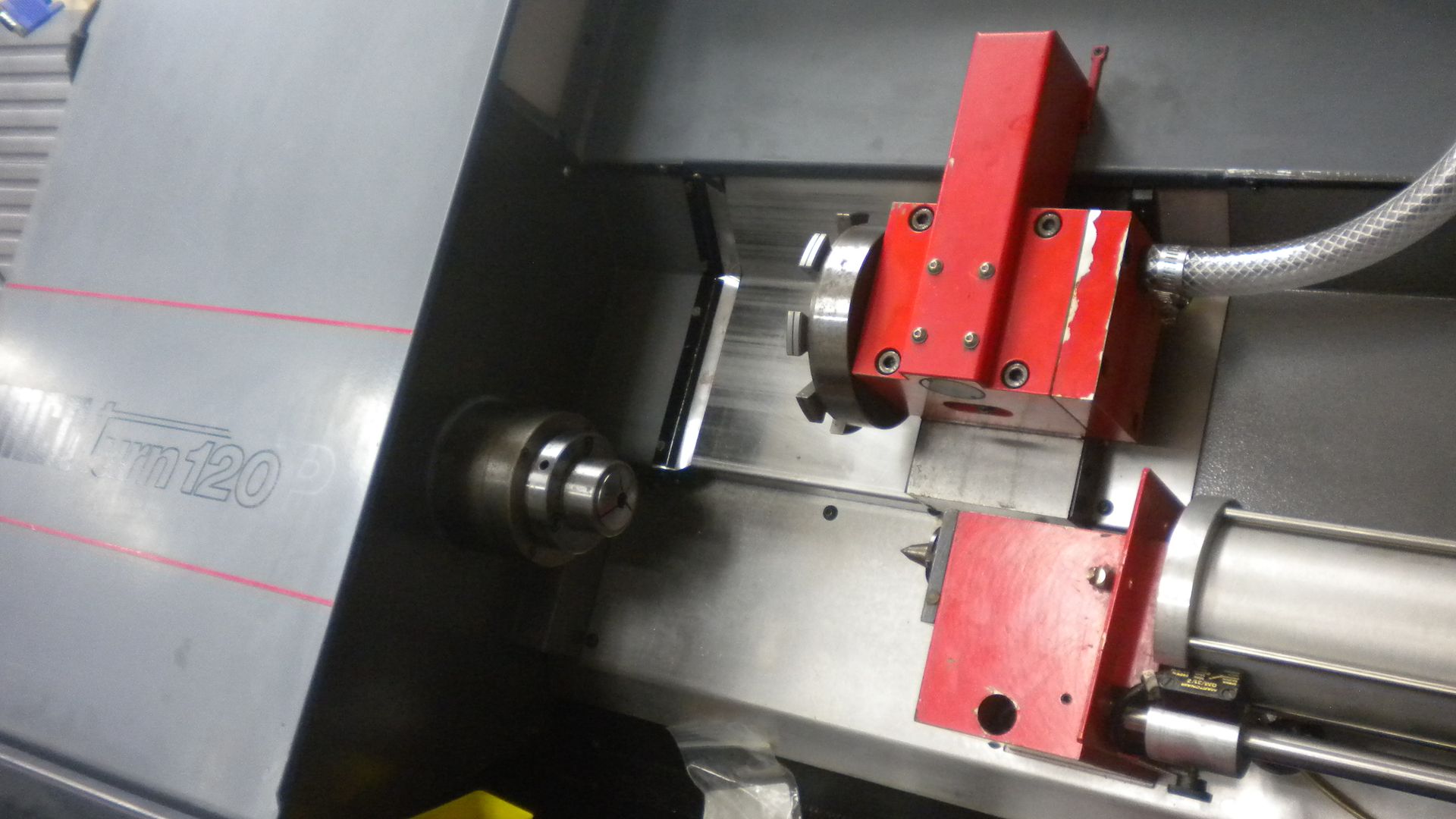

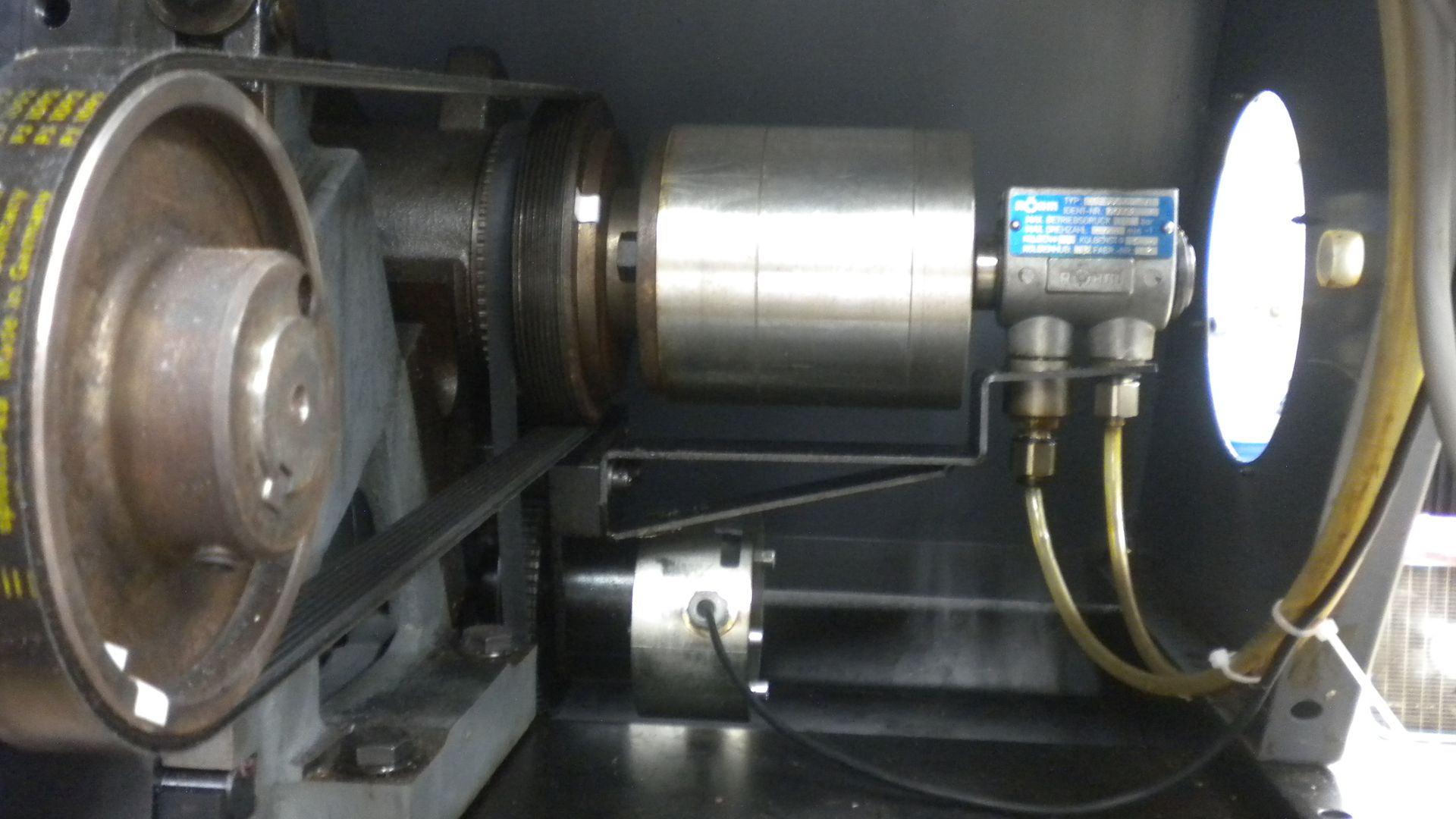

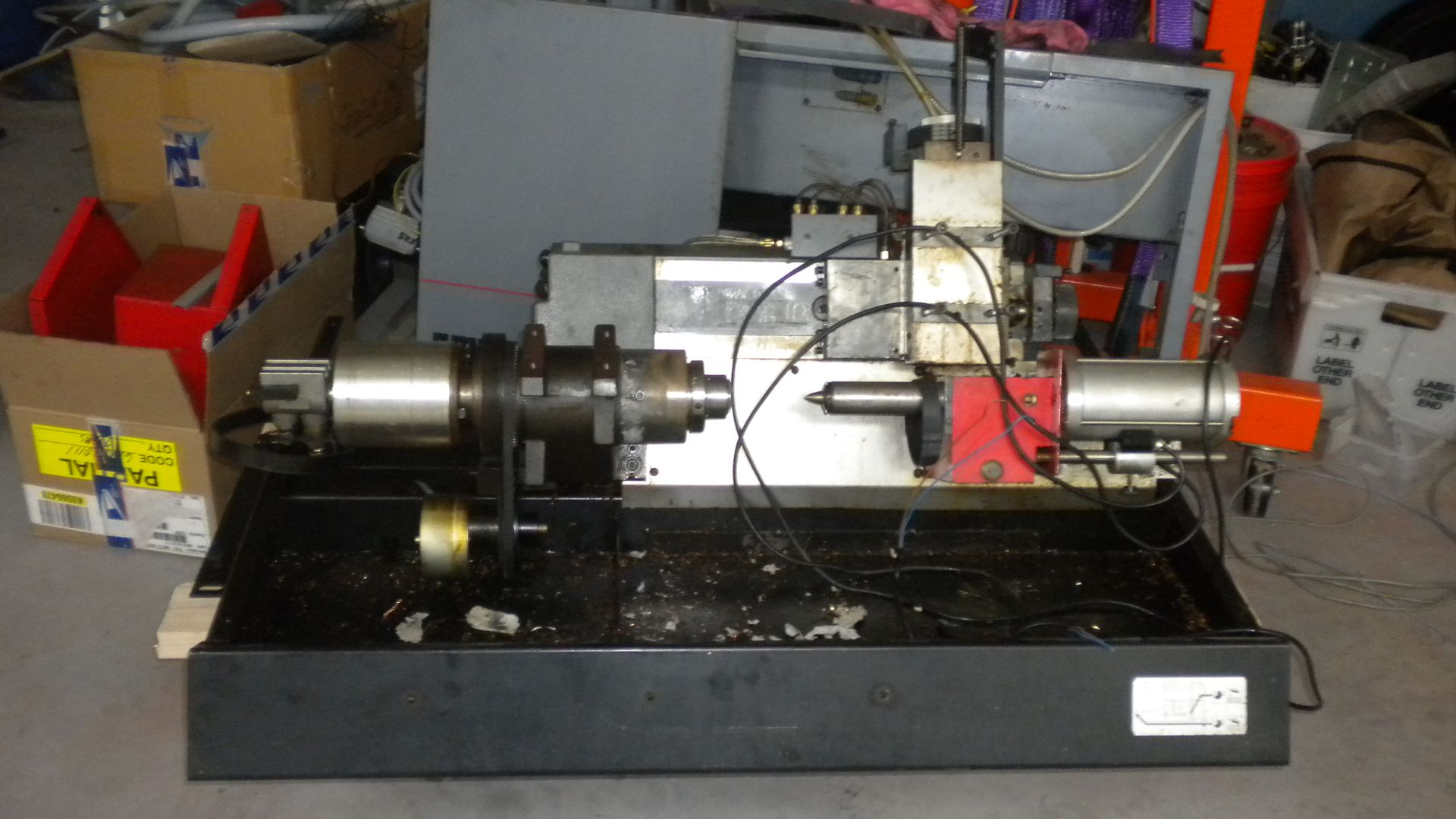

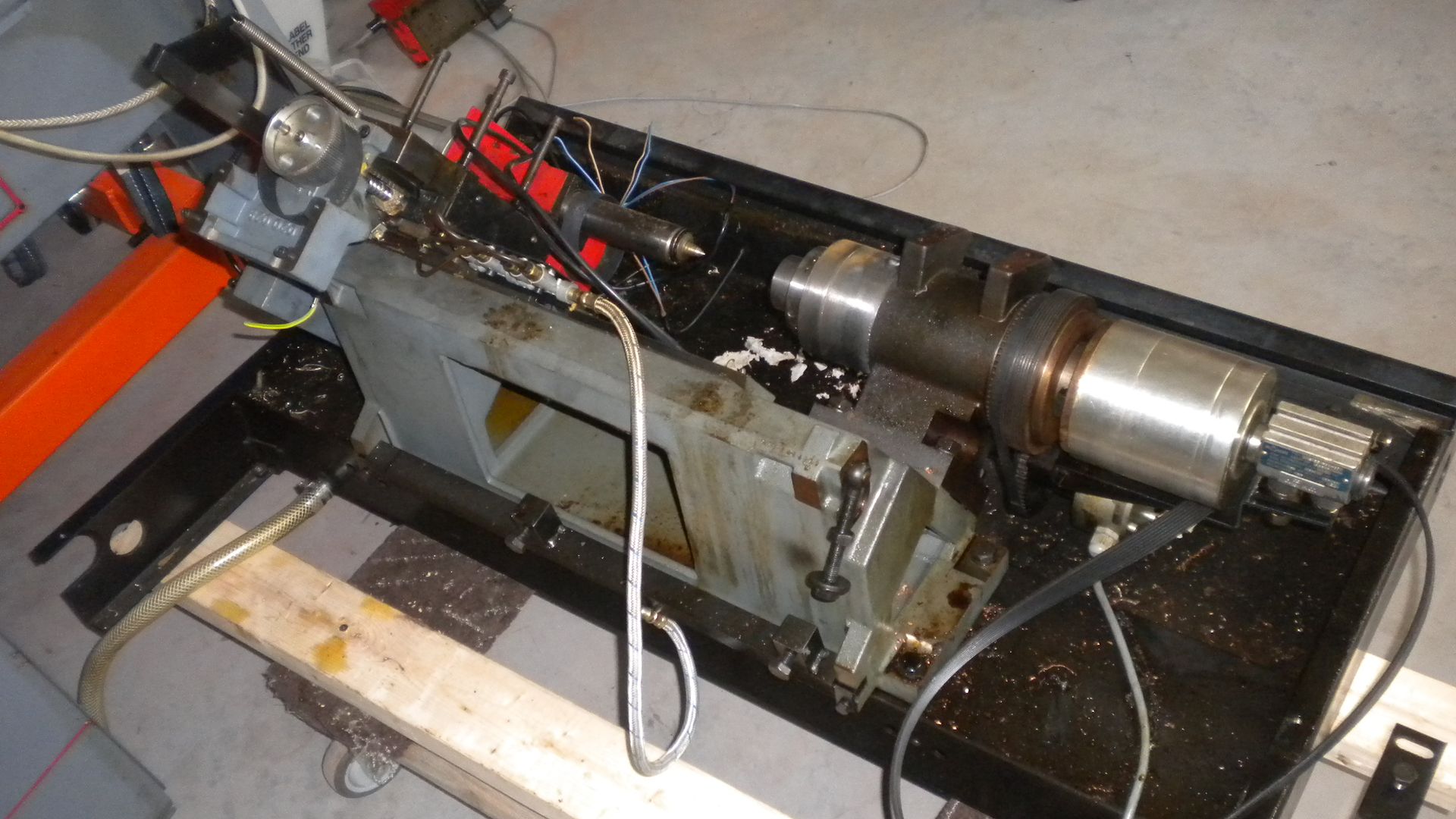

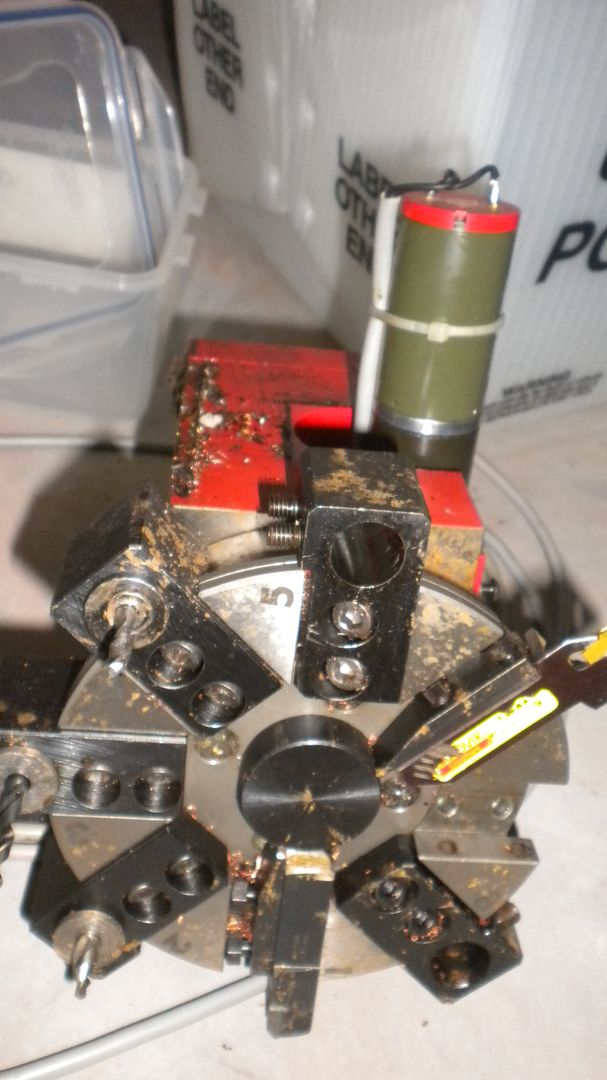

i have a Compct 6P wich is similar to the 120P. A very nice and sturdy machine. My machine was in a very good condition so i changed nothing. Wich chuck will you use? The pneumatic one opens only 3mm. I thought about changing the chuck to a bigger manual one. But then i realized that if i do so i could not use boring tools. Not so good for hobby use. I think i´will have to buy the manual chuck from Emco but it costs about 650 €.

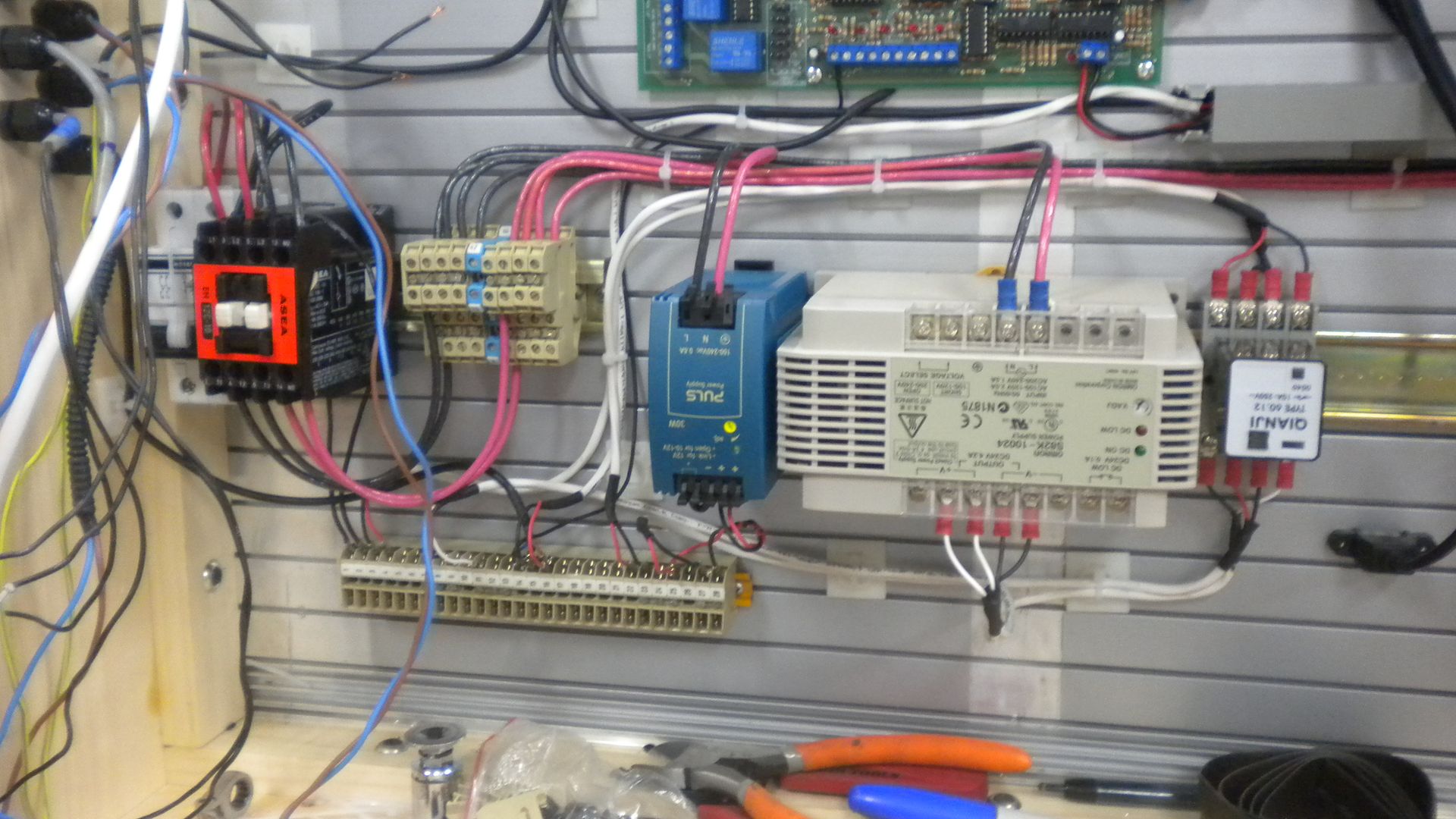

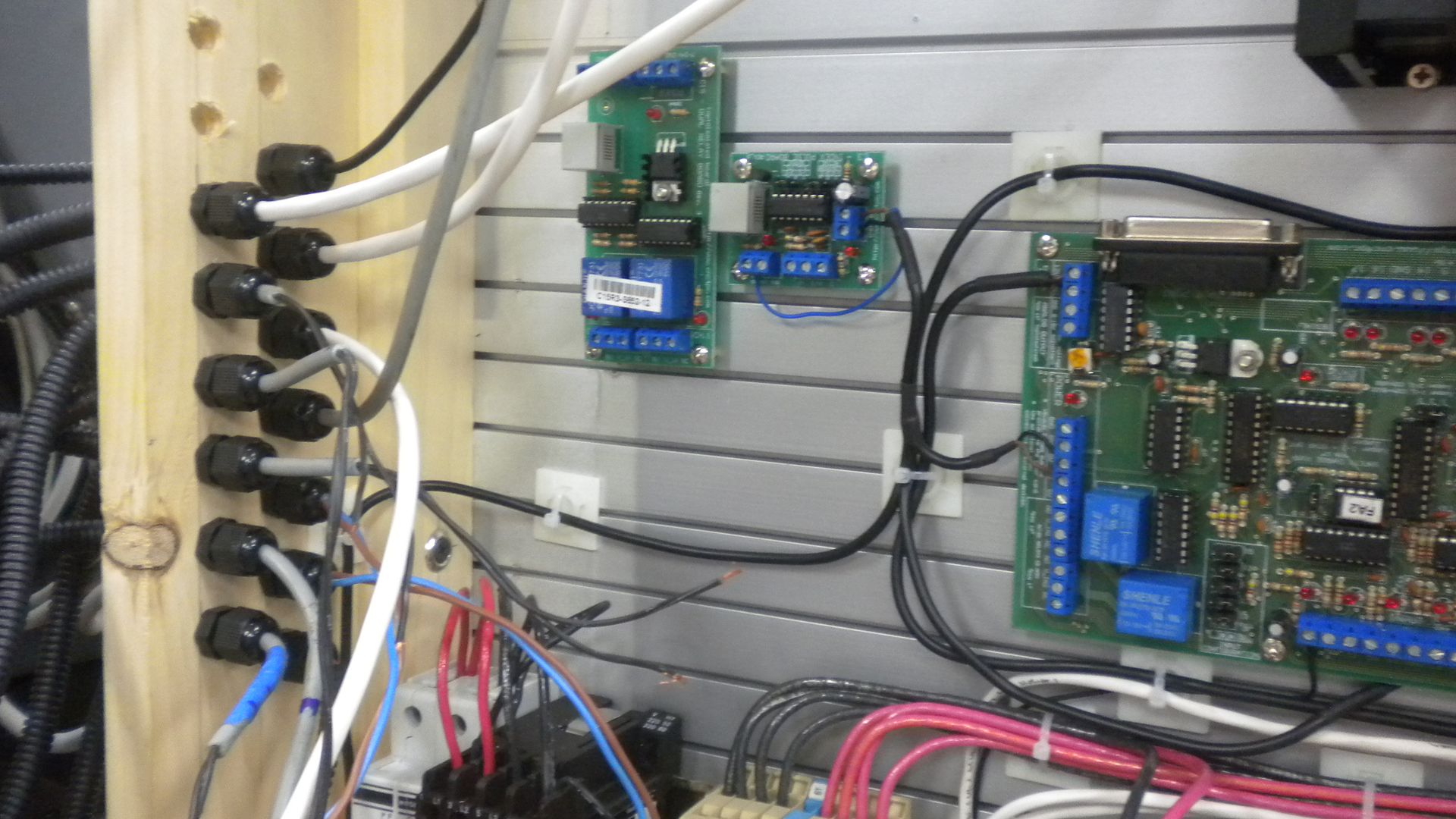

I´m very interresed in your conversion.

greetings Rene

Reply with Quote

Reply with Quote