well , now it works and using only the 0-10V output of the board and i am grounding the X1 VFD pin with a relay output on the board and Mach3 controls it ON/OFF but it doesnt seems to control the rpm yet , probably not setup well on Mach3 or the VFD settings ...

the actual goal is to find the correct settings of the Sunfar E550 to receive the RPM target and set the Mach3 control output right so they work together !

i am using this thread to help me setting it up but i haven't been able to control the RPM yet ,

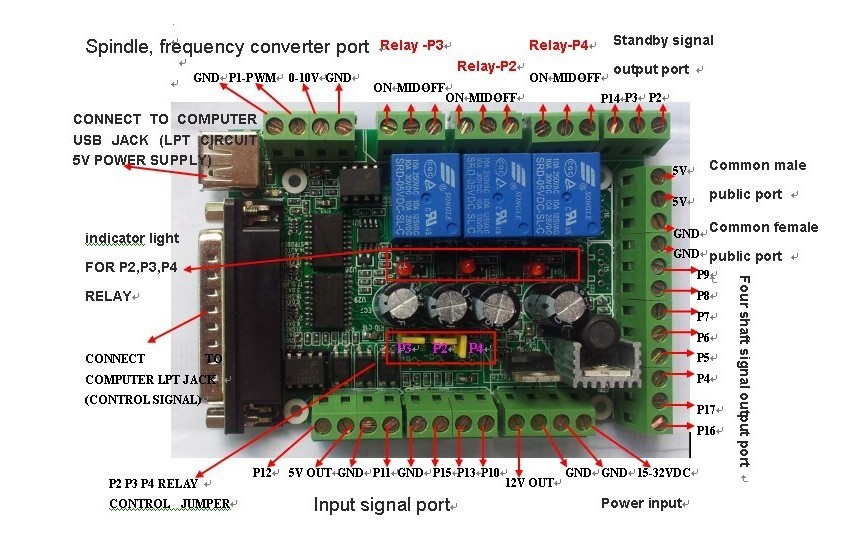

also checked the output voltages on the BoB outputs and when ON/OFF spindle and playing with the target RPM and i always get the same voltages measures in between GND- 0-10V ==== 10mV and GND- PWM === 215mV , they never change ... confusing !

https://www.cnczone.com/forums/spind...p-problem.html

took some screenshots of the Mach3 settings i got now , something i got wrong ? probably !

Reply with Quote

Reply with Quote