- Shoptask lath drive train replacement

-

Registered

Shoptask lath drive train replacement

Shoptask lath drive train replacement

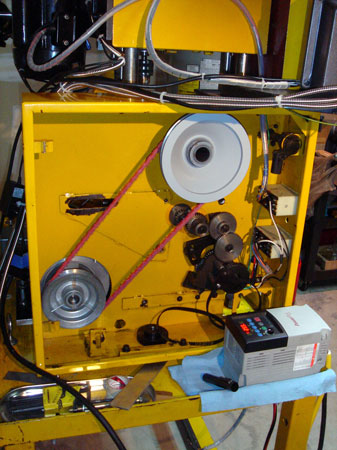

I have recently converted to a 3 phase motor with a VFD. I have noticed several photos of other shoptasks where the motor pully drives the spindle pulley directly. Just looking for advice on belt lenght a pulleys to make the conversion. I am using mach 3 and a new campbell controller to run the VFD.

Anybody got pictures of how to perform conversion?

Ray

Similar Threads:

-

-

Registered

-

Registered

Thanks so much!!!!!

This is exactly what I've been looking for.

Just wanted all the extra noise removed and a smooth spindle.

I have my wrenchs in hand, and will start looking for the belt you mentioned.

The pictures speak a thousand words....

Thanks again

Ray

-

Member

Re: Shoptask lath drive train replacement

Re: Shoptask lath drive train replacement

I am considering conversion to VFD 3 HP 3 phase. If I must do only one axis to start with, which would you suggest first? The mill or the lathe?

-

Member

Re: Shoptask lath drive train replacement

Re: Shoptask lath drive train replacement

It seems that only you could answer that question since you know which function you use the most. However, I think once you begin the process, it would be sort of counterintuitive to do just one function since you would have to do all the wiring and installation of the VFD anyway.

- Shoptask lath drive train replacement

Tags for this Thread

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

[br]

Reply with Quote

Reply with Quote