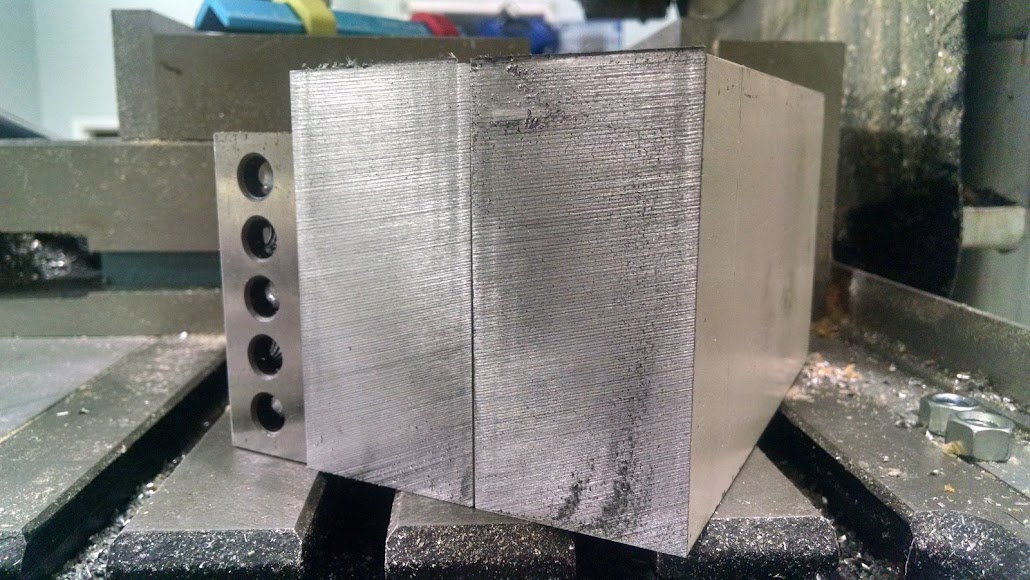

Found out last night that my cheap import vise does not use standard 6" jaws. I needed to make some 3" tall soft jaws, and was just going to use the standard bolt spacing for kurt soft jaws. But I decided to check if the set of soft jaws I ordered the other week fit my vise, before I did anything. And sure enough, not even close. Thankfully I only bought one set of soft jaws, I was going to order more. Looks like I will be making a trip to the local metal supplier to pick up some aluminum bar stock and making my own soft jaws.

Is this common with the import vises?

Reply with Quote

Reply with Quote