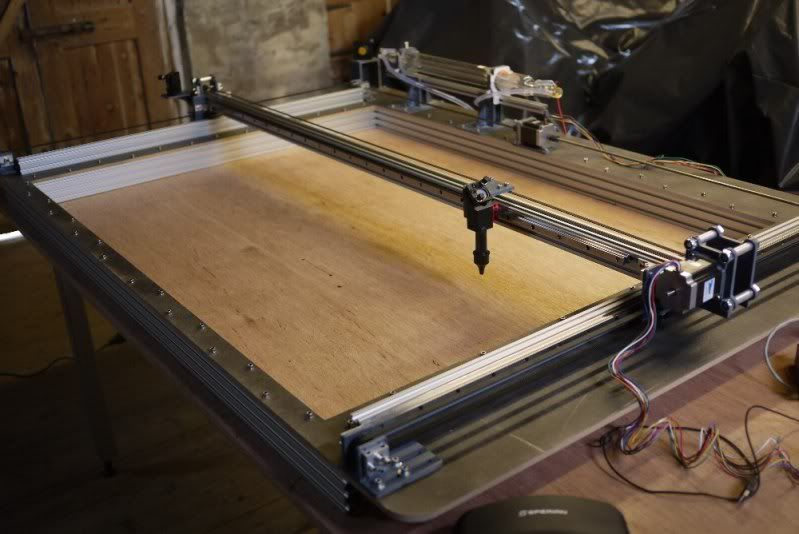

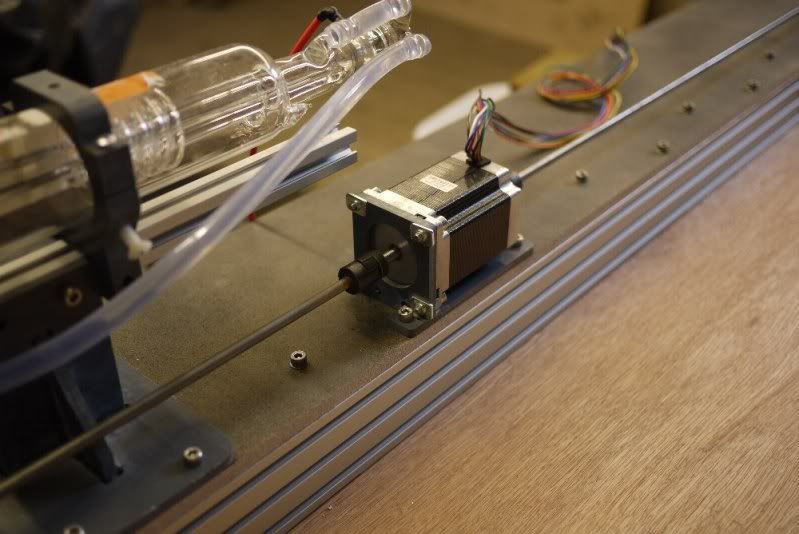

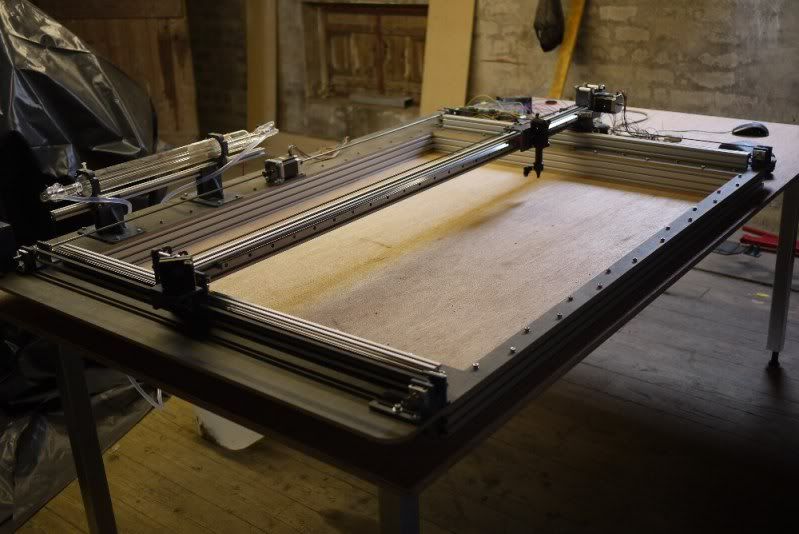

Looking good, just one suggestion. If you are looking for fast rapids you will experience a lot of whip on the rods that are attached to the stepper moving the Y.

Something to consider if it does turn out to be a problem. I like how the chinese ones to that with a larger diameter rod supported by pillow blocks on each side and stepper on one end.

Reply with Quote

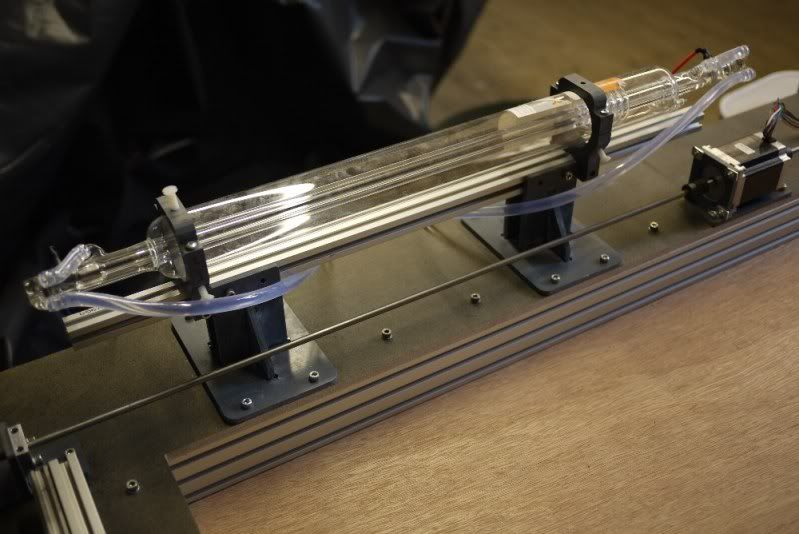

Reply with Quote have a word with Tweakie, he scratch built a laser/router/cutter that runs native code so he would be a great place to start for advice (as well as being one of the smartest guys I know)

have a word with Tweakie, he scratch built a laser/router/cutter that runs native code so he would be a great place to start for advice (as well as being one of the smartest guys I know)