Happy Labor Day Mark,

Strange it should have still worked just with opposite polarity.Great. What did you change?

I had the polarity of the micro relay board incorrect,

Actually Kanalog Optos are like a switch. Depending on how its is wired when the "switch" activates it can either source +24V or sink to 0V.however the signal that Kanalog supplied to the micro relay board is -24VDC.

First observe Input Bit 143 on the digital IO Screen. Does it come on when EStop is pushed and go off when not pushed?We (Jim and I) did add another input (OPTO 7+) from the CR1 relay (pin 24) and a -24VDC to the other side of the input (OPTO 7-). When the E-Stop button is depressed it will deenergize the power to the servo contactors, thus shutting down the servos. I have confirmed the proper start-up and button operation, everyone is Happy on those circuits, I can go ahead and clean up those wires and place in their permanent home on the panel.

Will I also have to do SetBit(143) on OPTO 7 input to verify?

Inputs can not be set or cleared. They can only be Read. Later in a forever loop you might read this bit and if active do something like disable all the KFLOP Axes which will cause any program to abort.

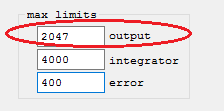

No, please read more carefully. That is a motor Configuration file not C Code. You might also read this.Will I copy the KanalogInitialPID.mot to the C Code ->clipboard button on the Config screen, then load the channel?

Reply with Quote

Reply with Quote

This C Program can also enable anything that needs to be enabled. You might read

This C Program can also enable anything that needs to be enabled. You might read