Thanks,

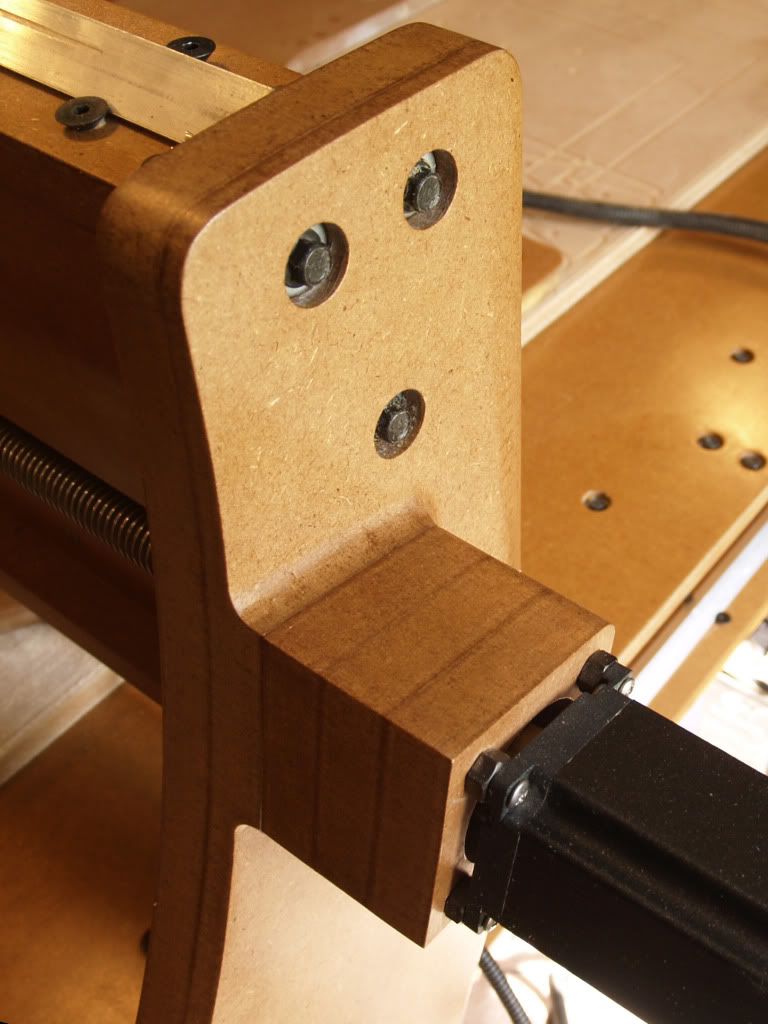

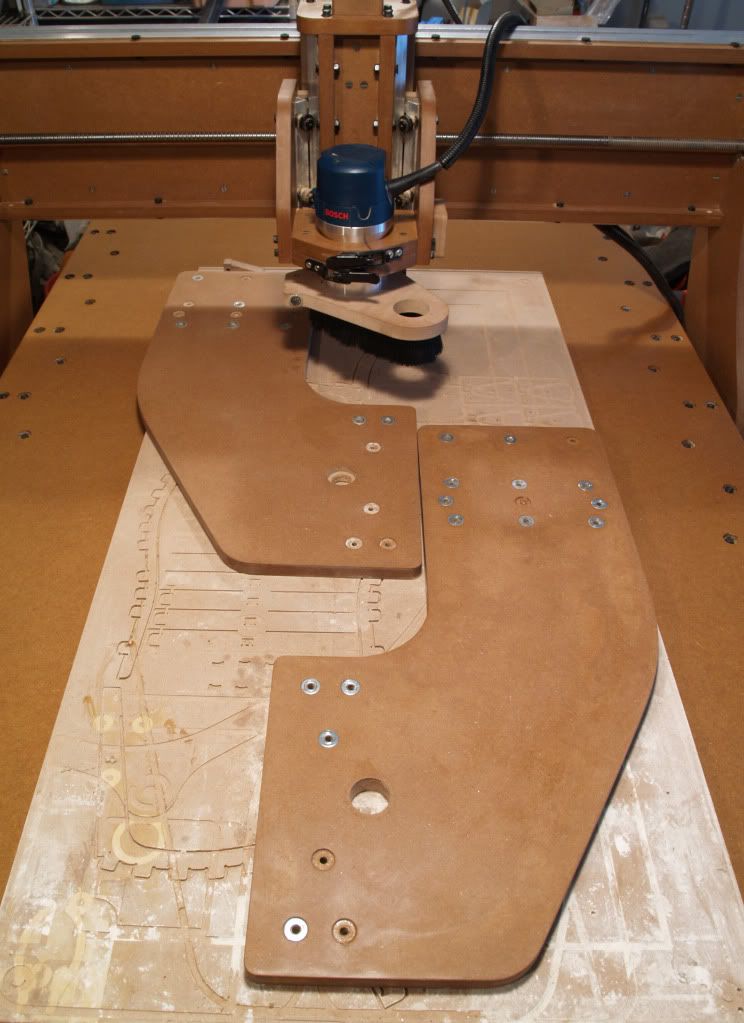

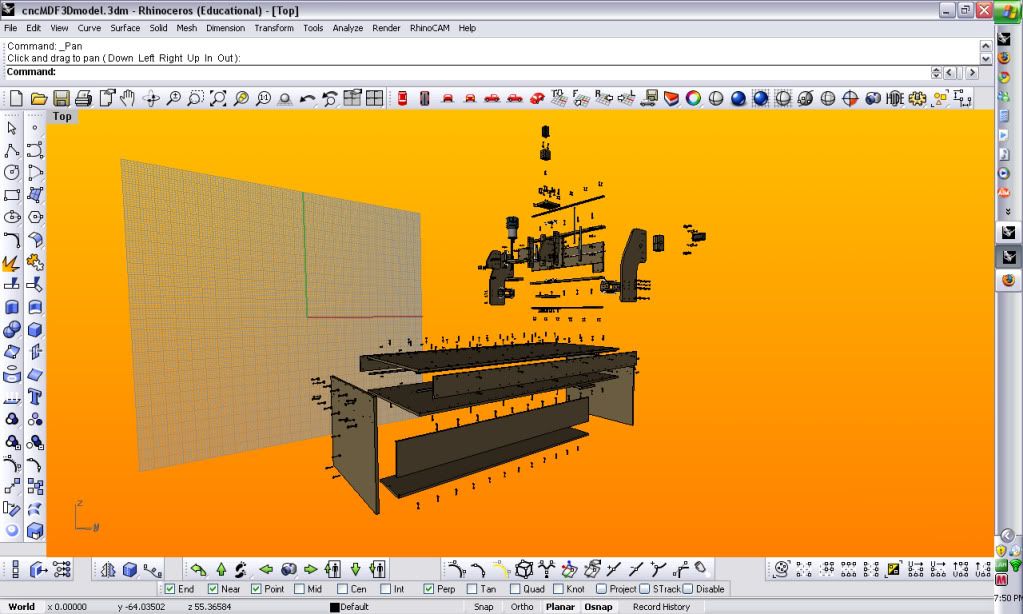

I imagine it would be possible to make it out of plywood, however I couldn't with my limited tools. Also, it is harder to find a perfectly straight piece of plywood not to mention its cost.

As far as the lighter argument, if you are building anything ~4' X 8' it is going to be heavy. CNC machines only benefit from weight from an accuracy stand point. I realize this negatively impacts the acceleration of the machine, but would you rather have better parts or impress your friends with the jog speed?

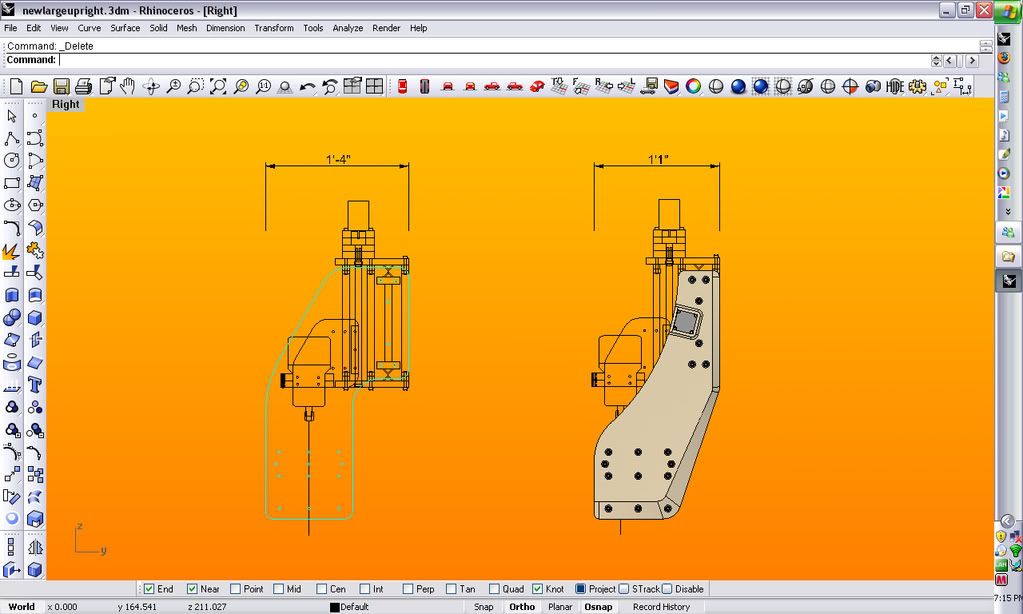

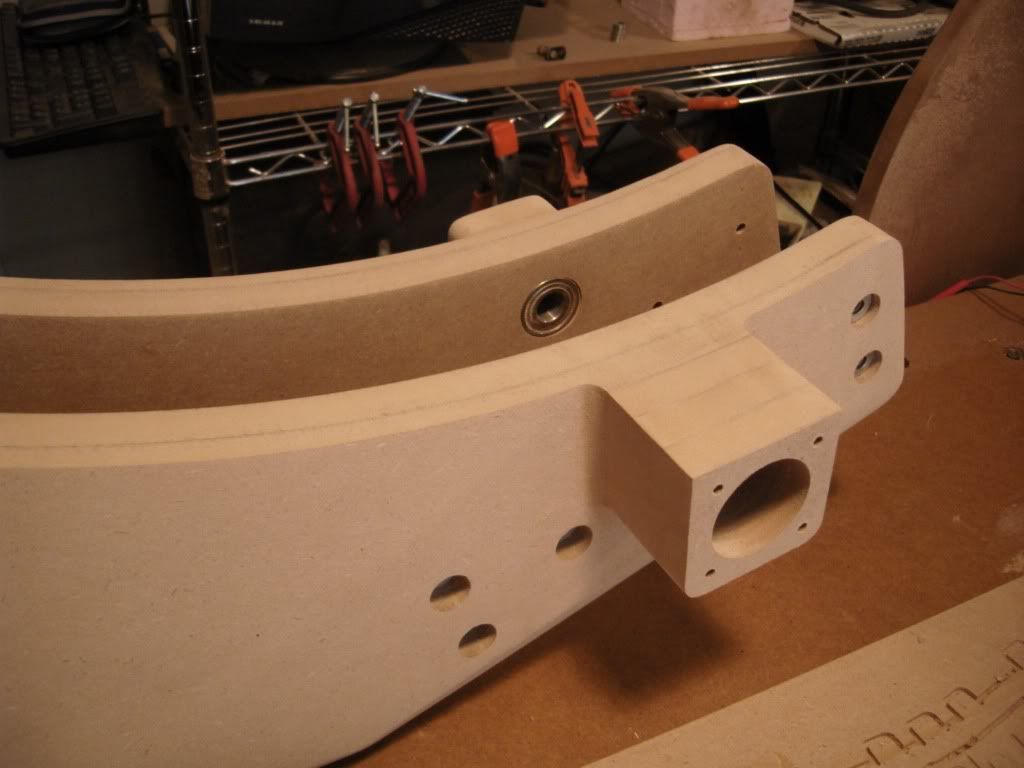

My next machine will use MDF and aluminum and will only be about 48" X 30" Mostly just to try out some ideas I have had since finishing my current CNC but also to have the ability to move it without complete dis assembly or calling 6 friends. Maybe this one will also have a shockingly fast jog speed

Reply with Quote

Reply with Quote

Then if he wanted something, he does not have to buy it where part of his purchace cost goes over seas but stays in the country.

Then if he wanted something, he does not have to buy it where part of his purchace cost goes over seas but stays in the country.