Hey thanks

The surface replication worked perfectly for me. I didn't really know what to expect going into it, but yeah - no complaints on that front.

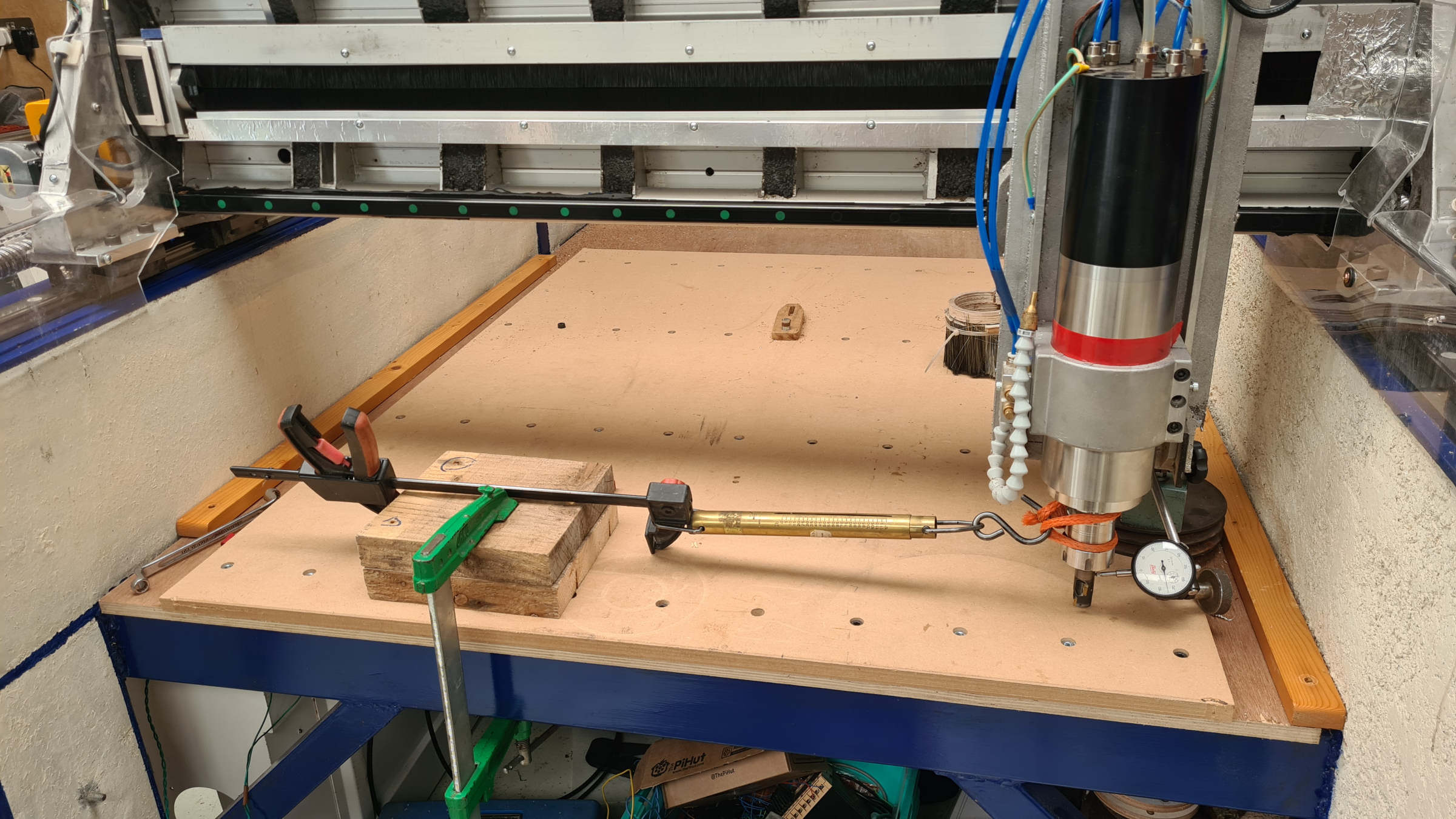

w.r.t. stiffness: I don't think it's in the same league as yours, being a big router really. I hadn't actually measured this, despite testing it on steel etc. So I had a look today...

By far the most flex is coming from the spindle plate, as it has a lot of z travel (400mm from the bed to the gantry, and it has a bit extra to reach things in the gap). I always thought that if I was going to be machining metals I would do them towards the top of the z's range....

So fully extended out it's getting 0.14mm deflection at the tool when I put 30kg of sideways force on the tool holder... What surprised me is that deflection is roughly the same when I pull in both the x and y direction. I expected to see much more parallel to the long rails when it's trying to twist the gantry and bend the z spindle plate in the direction I assumed it would be weakest. Am I right in saying therefore a rather disappointing 2.1um/N

When near the top of z travel where I would have it (if I possibly could for metal), it's deflecting 0.04mm with 30kg force. Again both the x and y directions were the same. When I measure parallel to the gantry travel (what I call x), so not like the photo, I put the spindle in the middle of the 1.2m gantry, assuming that would give the most deflection... a bit better 7.5um/N if my calls are right?

One last thing to note is that the ballscrews on this are 20mm pitch and with the servos unpowered I can push it by hand, so I did the tests with servos on, and I could hear them working as I cranked the force on.

Ok hope that helps.

Reply with Quote

Reply with Quote