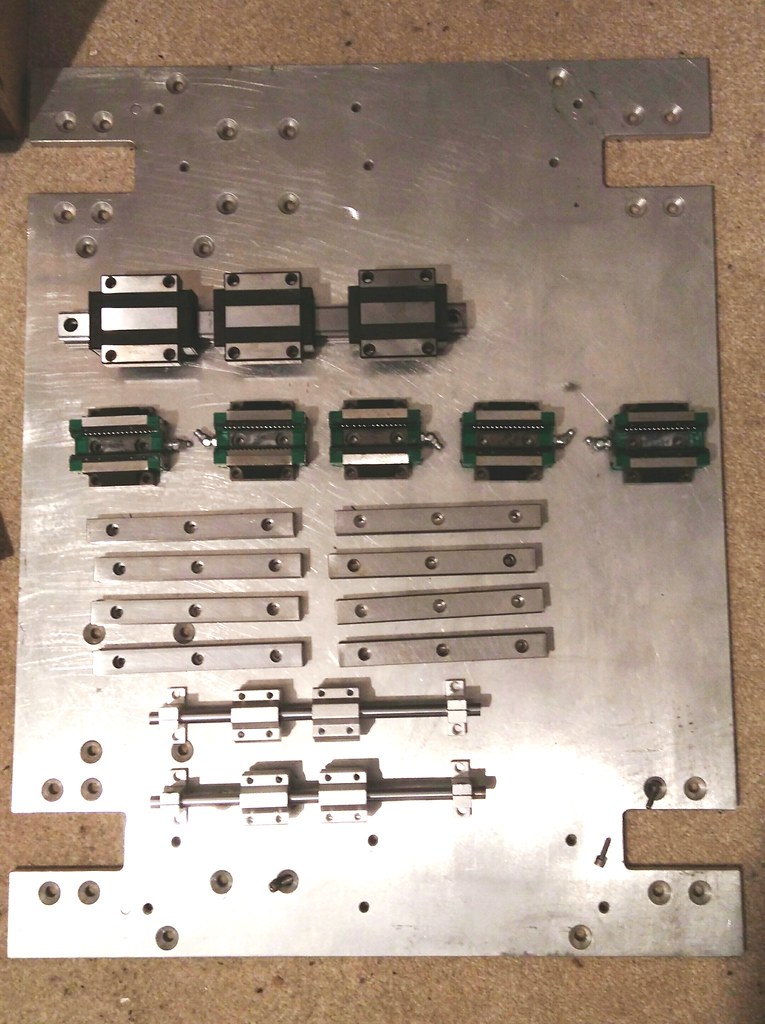

Those 8 rails are really too short to build anything but a tiny CNC machine. The 5 smaller bearing trucks would be fine for your 3'x2' router's X and Y axes- just get some rails that are long enough, leaving room for the trucks, and another 3 trucks that match them so you'd have 8 - you need 4 for each axis. You could use the ones on the top row for your Z axis; just get another rail the same length. You can mount that using one truck per rail, although it's better if you use 2 - in which case you'd need another one. The stuff on the bottom 2 rows might make a nice latch for your shop door, to keep people from bothering you when you're in there building things. Spend the money you've hoarded for the spindle and electronics on the things you need for your frame, and hope Santa shows up again when it's done (Christmas is just around the corner)...

Reply with Quote

Reply with Quote