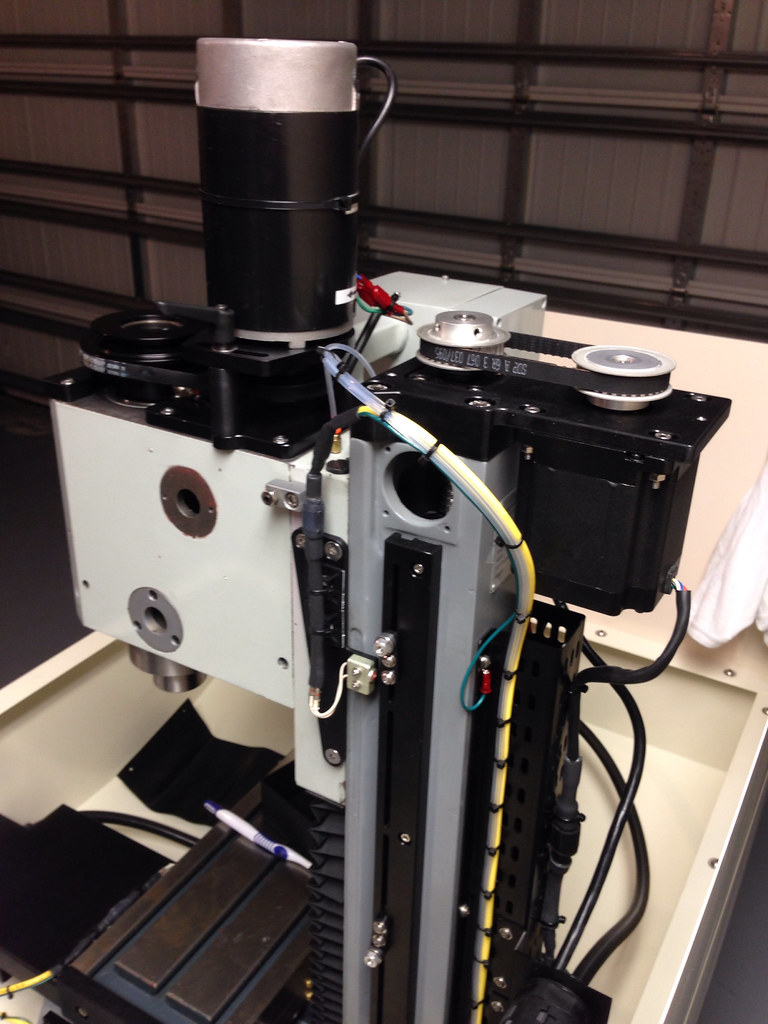

Arizona, thanks for the feedback; I switched to 16 AWG wire on the NEMA 34 Stepper on the Z-Axis. Also, thanks alex_ku for the tip about the gas shock, you were right, so I flipped it around.

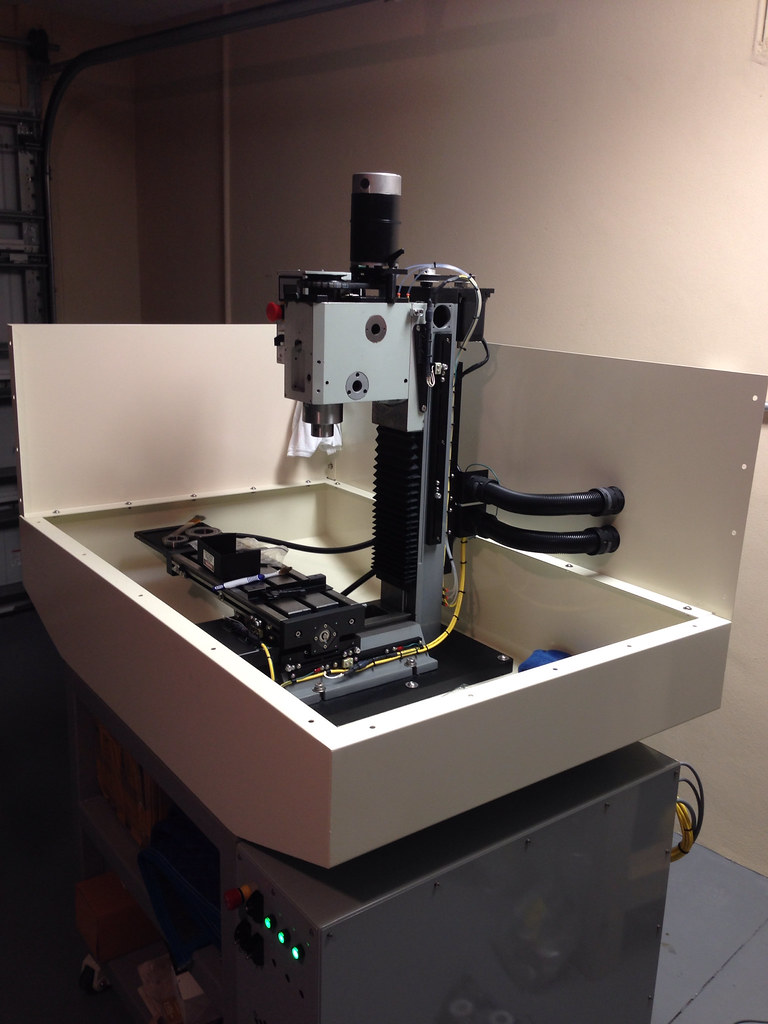

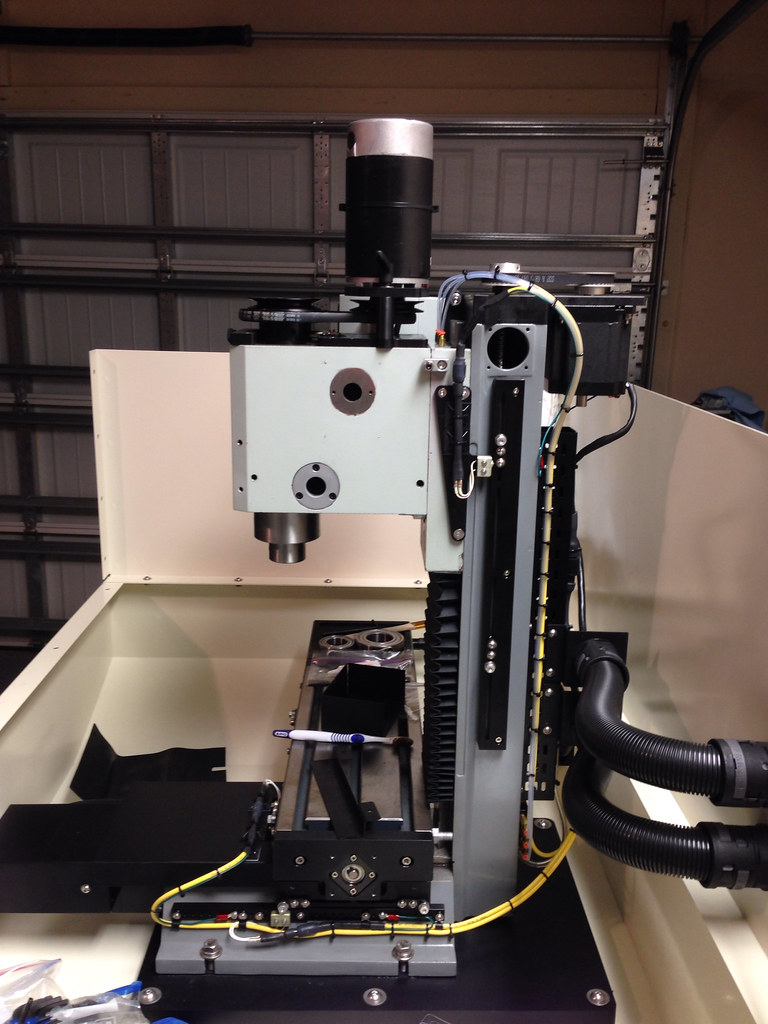

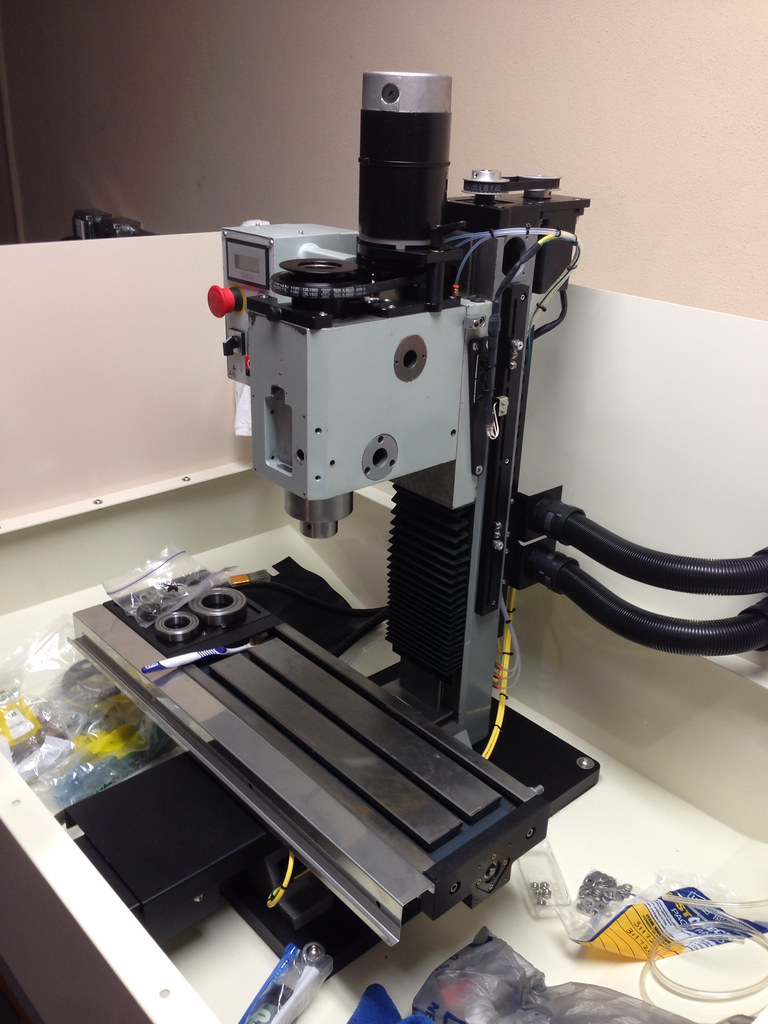

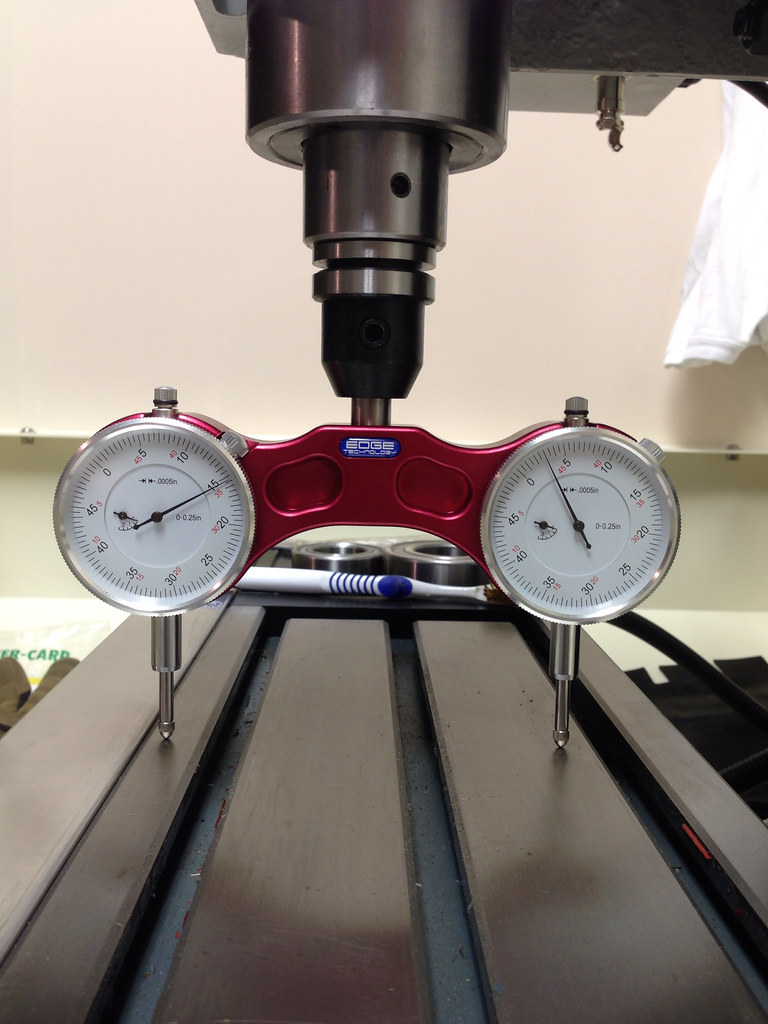

I have been doing some work so I thought I would post up some pics. I should be done running the cables tomorrow and hopefully have it moving by the end of the weekend

Putting together the front panel:

Putting capacitors across the leads to the fans to reduce noise (100uF, 63VDC):

Fans wired up:

Stepper cable for inside the enclosure (cables are shielded, so grounding one end at a min or the shielding will work against you):

Everything inside the enclosure all buttoned up (the wire duct made a big difference):

Enclosure powered up and working:

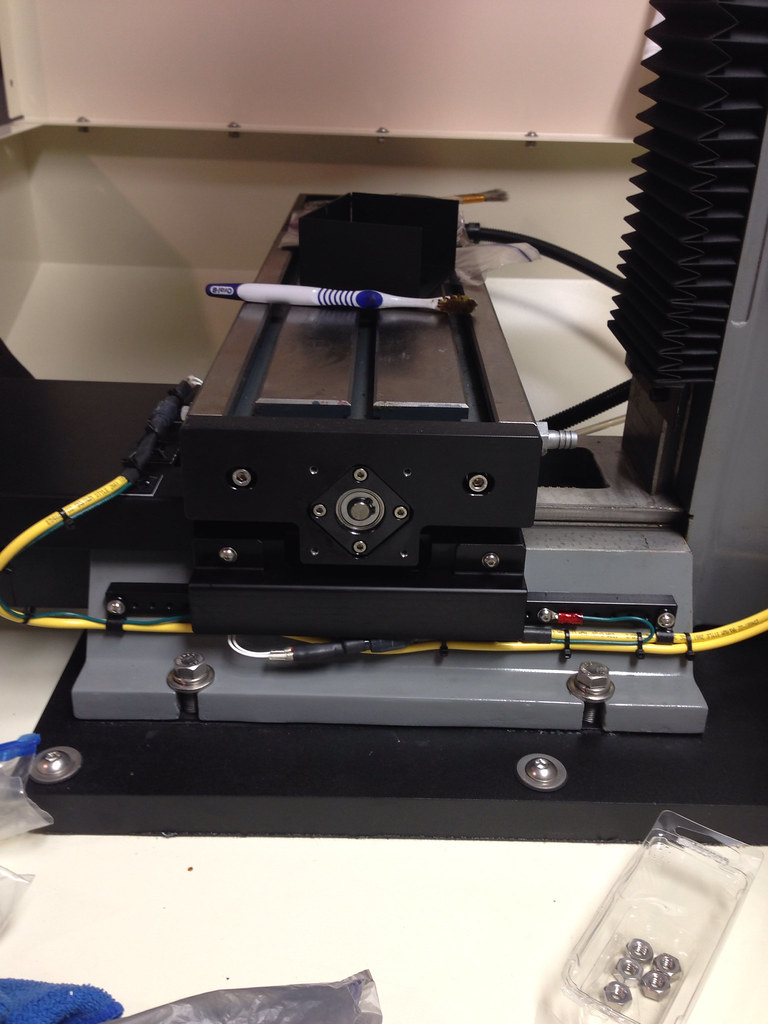

Starting to run cables to the limit switches and steppers:

Reply with Quote

Reply with Quote