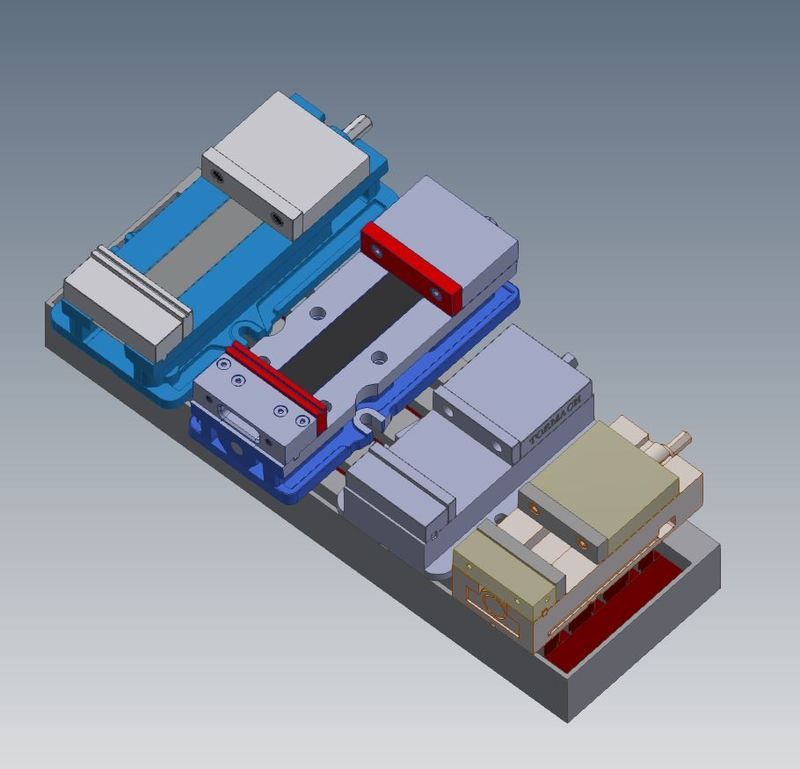

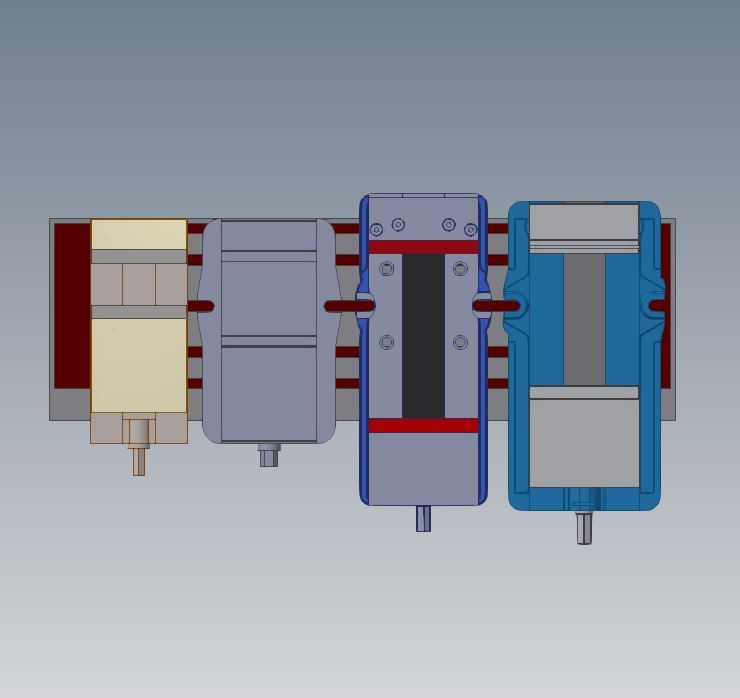

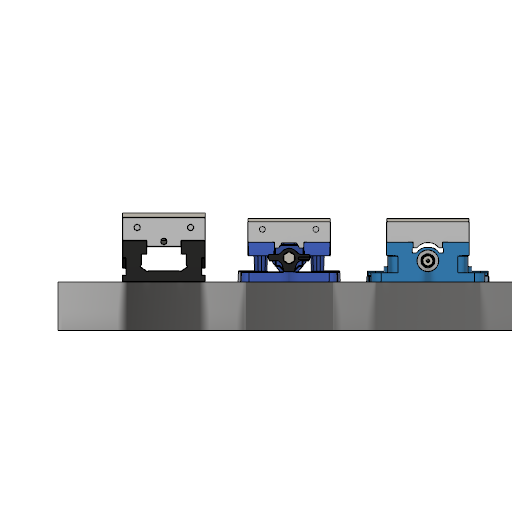

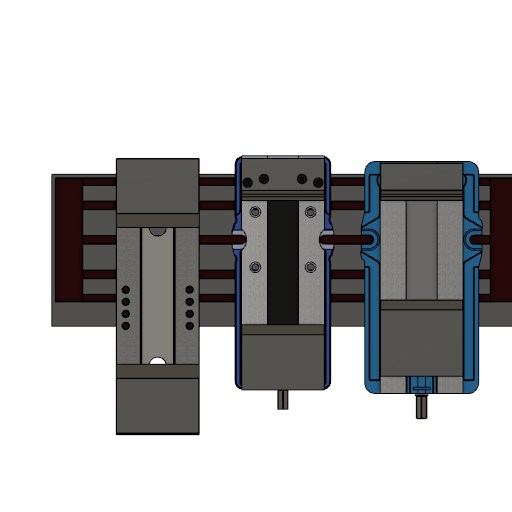

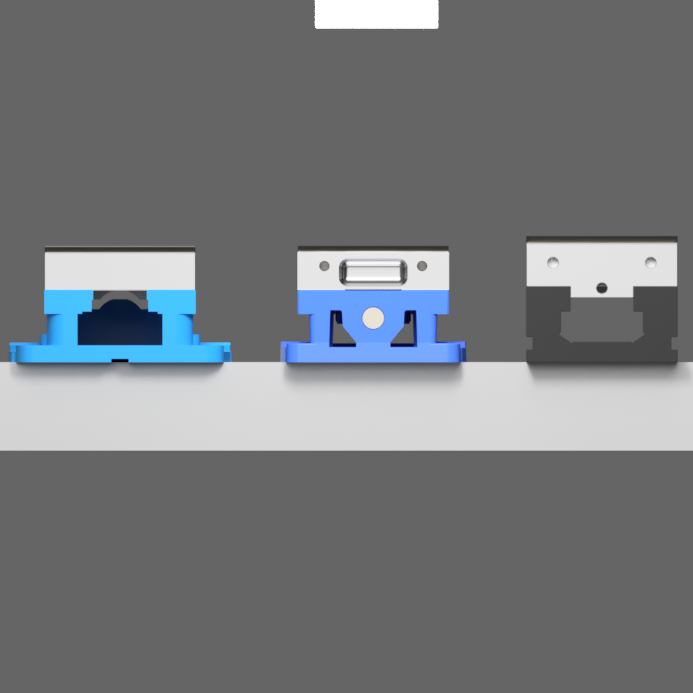

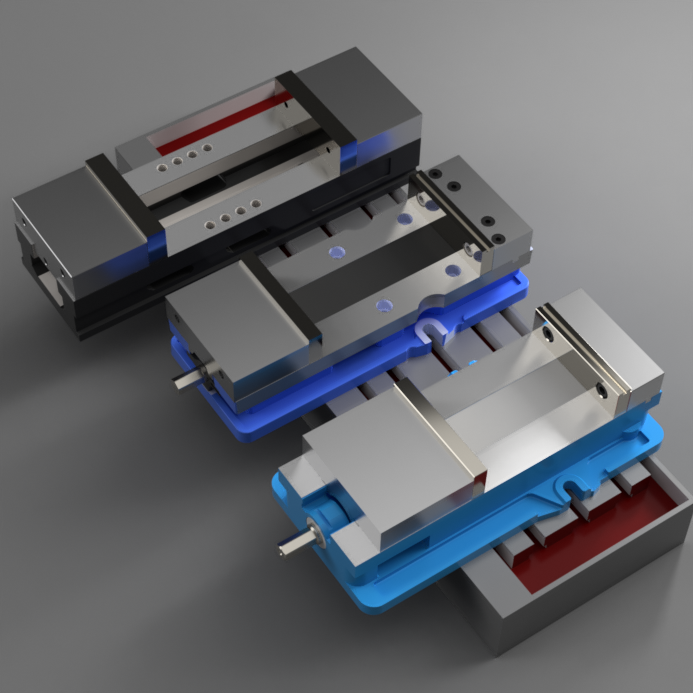

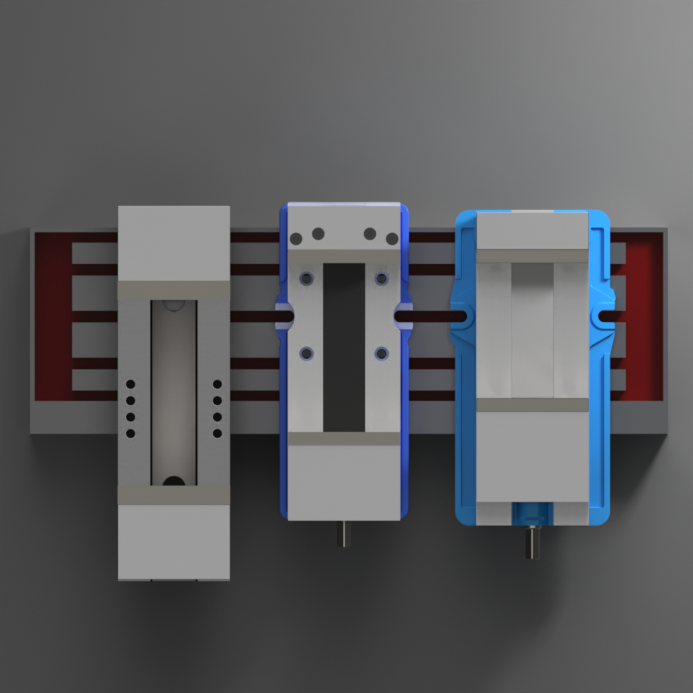

Nice models and renderings!

My Tormach 5" cnc vise hangs over back more then your Kurt 6" vise looks like in the pictures. It was a couple years ago but I looked at dimensions and went with the more expensive Tormach because it fit better. BTW I think parts of those Kurt vises are made about 2 miles over the hill from me.

Anyway nice pictures

Reply with Quote

Reply with Quote