Ive been wanting one of these for a long time.

I am very curious as to how your spacers work out. I like the idea of filling the slots to help with chips. Im also very curious on the "rigity" of the areas between the spacers. I wonder if there may be any "harmonics" in those areas that may cause surface finish issues. I dont know and thats why Im curious.

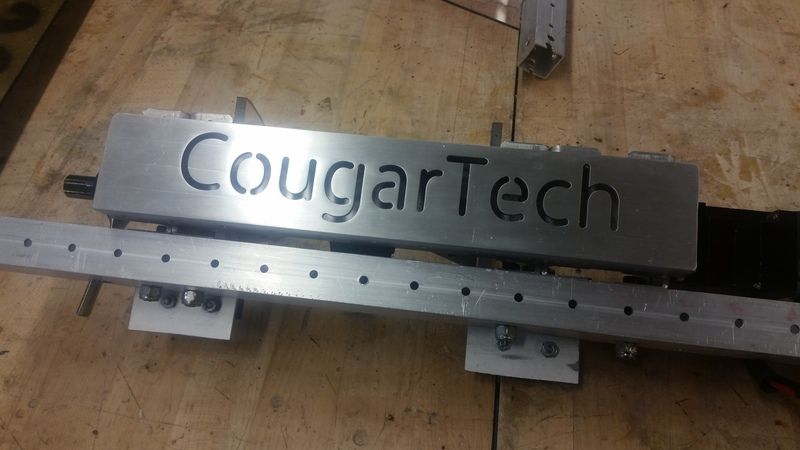

These plates look very nice. Congrats on the new toy and please share your experience with me on these things.

Reply with Quote

Reply with Quote