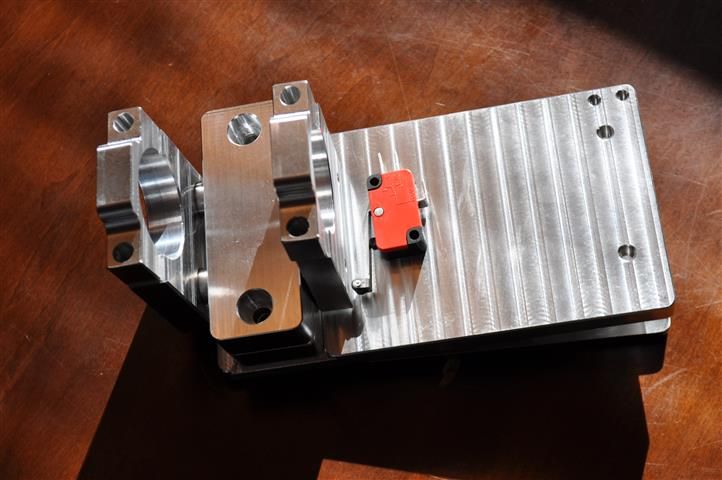

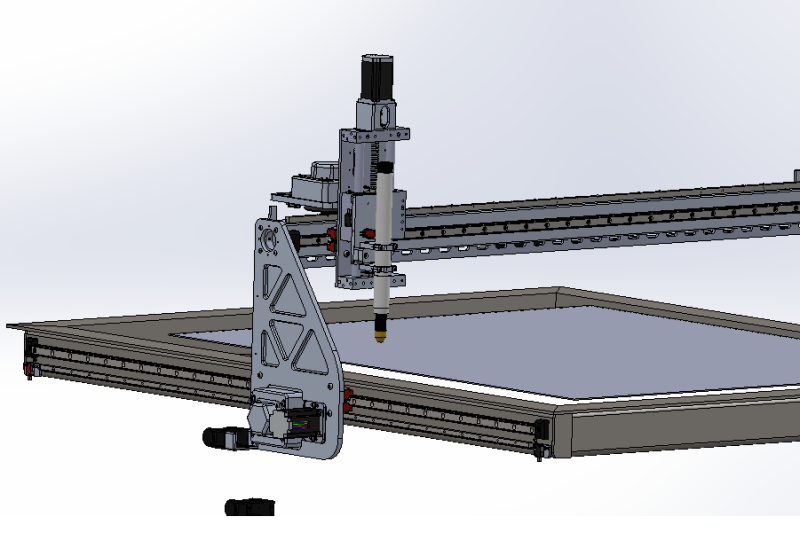

Finished the Z axis motor mount.

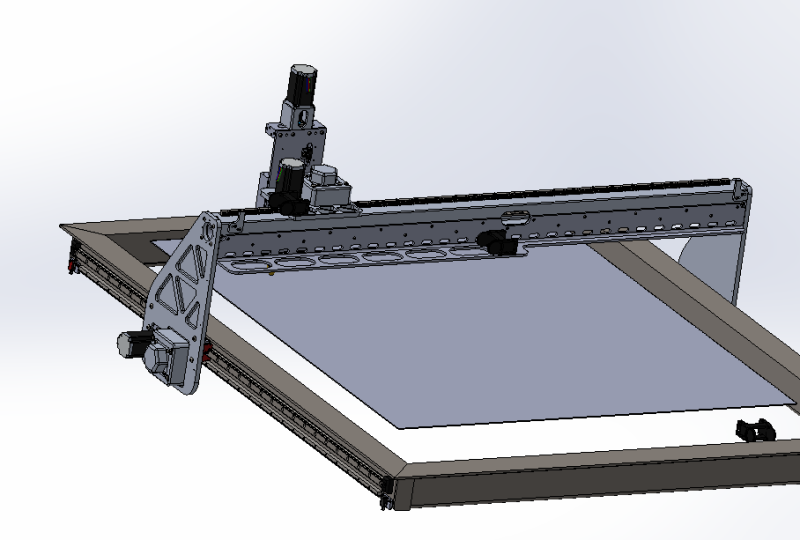

Some pics.

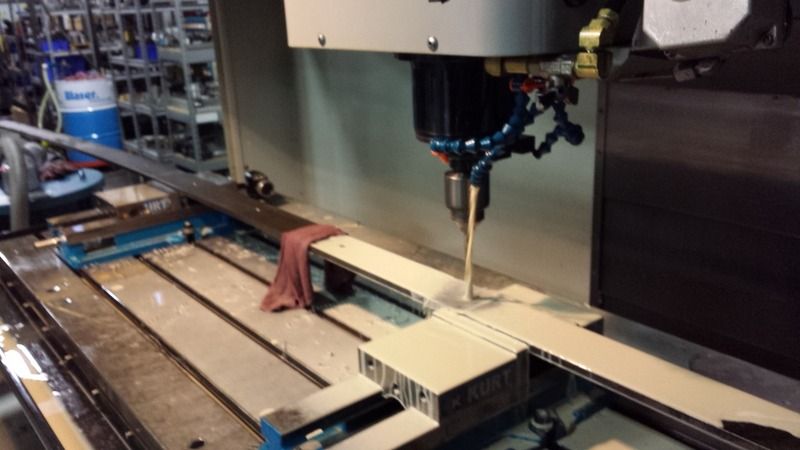

1st Operation. Bottom side with locating bore/slot for 1/4" dowel pins. Machined the motor locating bore right though in this operation as well to ensure it all lines up.

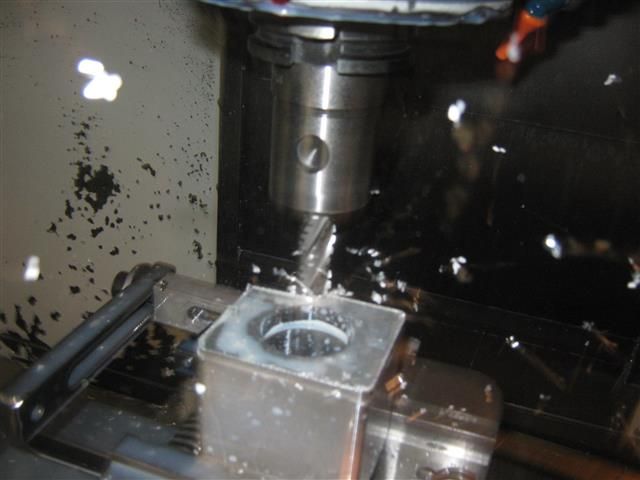

Machining 2nd operation. No finished photo of this side but it was just faced and threaded for the motor to mount to.

A slot cut in two sides to save some weight and allow me to tighten the motor coupler screws.

Done

Reply with Quote

Reply with Quote

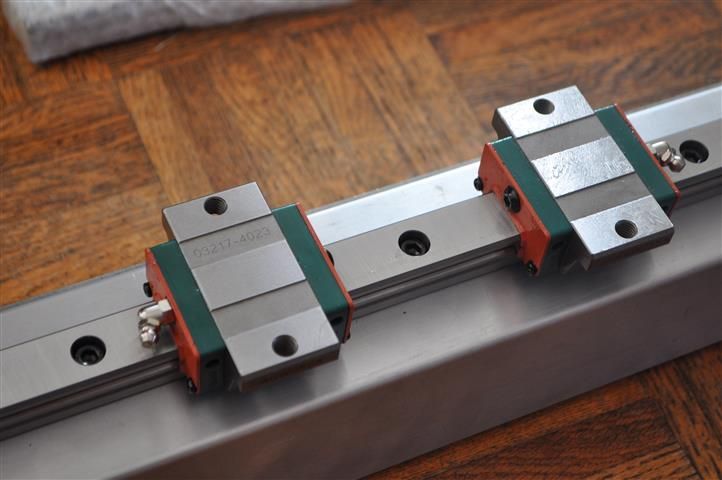

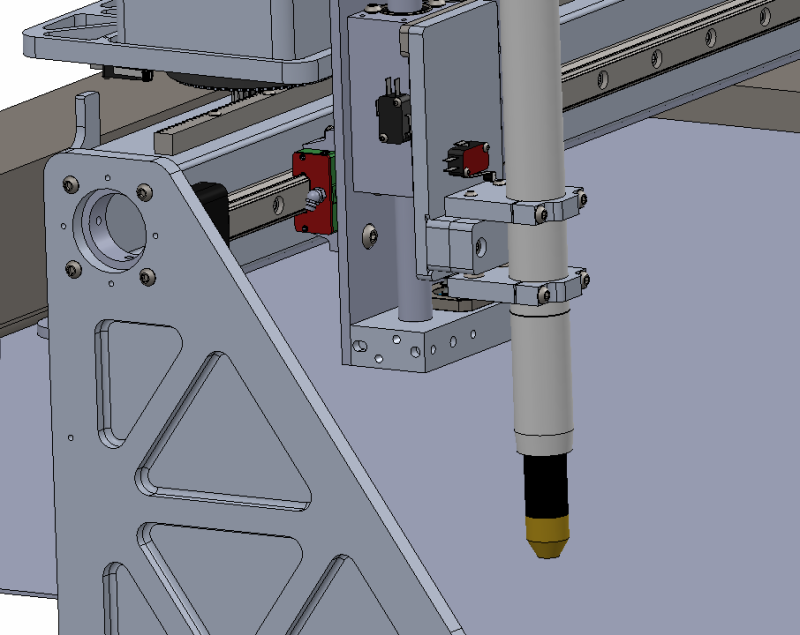

Upper an lower Z axis linear rail and ballscrew bearing mounts.

Upper an lower Z axis linear rail and ballscrew bearing mounts.