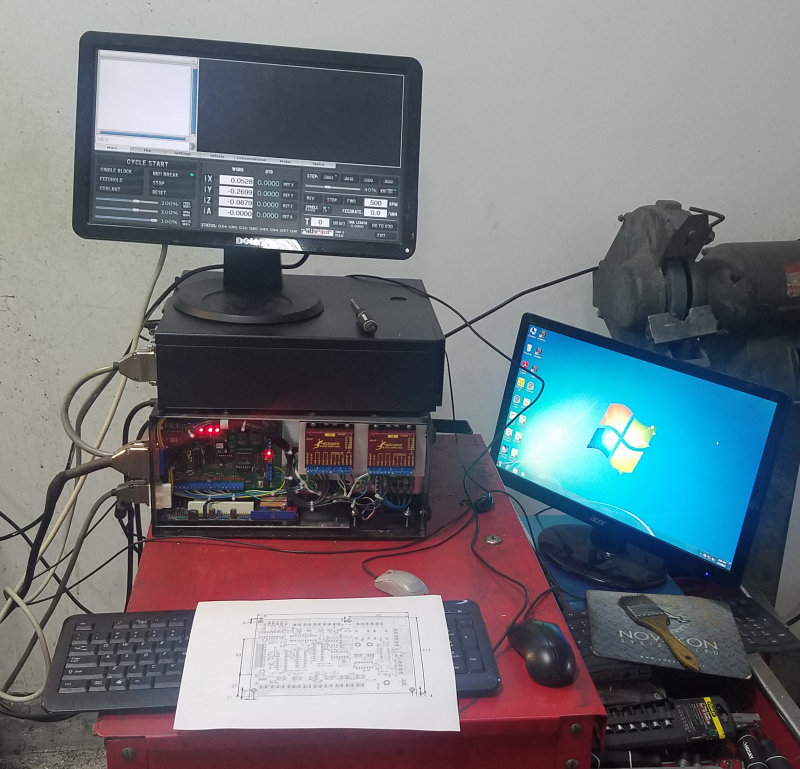

Changing the 'in' to 'in_not' as advised now has the limit switch light in PP 'off' when PP starts.

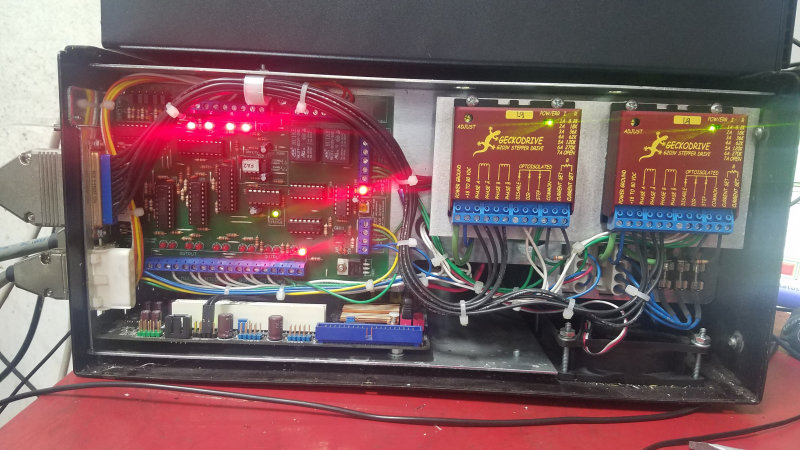

I changed the jumper on the BOB to disable the charge pump, and as a result I can jog the axes and start the spindle.

The axes move in the correct directions per the jog buttons.

Jogging X continuous with the Tormach defaults gives 144ipm in PP. No idea how to actually measure this or how to set the parameters in the INI file.

The spindle turns only in the FWD direction, but this is the same as with Mach3. As I have never needed reverse that's not worrying at least to me.

BUT spindle ignores the speed requested in the Speed DRO and just accelerates up to 4000 rpm, which is my max. If I move the max RPM slider to less than 100% then I get a lesser speed.

With the spindle stopped, when I enter M3Sxxx in the MDI dialog box, the LED in the FWD button goes green but the spindle doesn't turn.

Reply with Quote

Reply with Quote

The axes move in the correct directions per the jog buttons.

The axes move in the correct directions per the jog buttons.