Perhaps something on using the serial port on the 'Pic List'

SmoothStepper (USB)

SmoothStepper(Ethernet)

Regarding stepper motors:

Jones on Stepping Motors

GeckoDrive 'Step Motor Basics'

Kress. A better spindle.

Chris

Hey everyone,

First post here as you can see. I am very interested in building my own CNC for cutting PCBs. I wouldn't mind doing some light wood engraving but it will be mostly for PCBs and future PIC Microcontroller projects when I have more time. I am very into the do it yourself deal and don't want a kit, just want to do it from scratch.

But I had a few questions before I get started on my own machine.

First, how do I overcome the serial port for the Stepper motor controller plans that populate the internet? I don't have a computer that still has that type of port. Not even sure the first computer I built in high school had one. Are there some plans for a usb one that I can build myself?

How can I learn a bit more about stepper motors? I've got ideas of how I want to build the frame and will probably model it using IronCAD or Inventor first but don't know much about the stepper motors. Just need help deciding what kind I ought to get.

And the last question that I have for now is on the spindle. I was thinking I would make the first machine using my Dremel tool since all I want to cut is plastic with copper in it. But are there cheap alternatives that offer a little more power? This machine only needs travel of about 12" X 12" X 3". That is all I want to start with and from there I will go bigger. The Millbox is what I want to make at some point, the versatility of a 3D printer as well would be cool (what the designer wanted it to be able to do at some point).

For now this build will be super cheap as I don't have a lot of money to throw at it. Or time for that matter, very heavy semester in the fall. I realize these questions are frequently asked but I didn't see much that pertained to such a small scale machine so figured that I would ask. Thanks everyone.

Similar Threads:

Perhaps something on using the serial port on the 'Pic List'

SmoothStepper (USB)

SmoothStepper(Ethernet)

Regarding stepper motors:

Jones on Stepping Motors

GeckoDrive 'Step Motor Basics'

Kress. A better spindle.

Chris

The parallel port is obsolete? And you want to know about stepper motors? Steppers were popular in the 70’s and early 80’s, than D.C. brush servos in the 80’s and 90’s than brush-less AC servos today. Just go to an old farts garage sale and buy an old computer, and download cncpro for “dos” (for free) to run it. Sorry about me being no help!

Thanks OCNC,

You helped a lot. I will be going through the information on the jones tutorial. Looks like it will give me the background info I need and want.

While the technology may be dated the issues that arise from using similar (updated) technology remains. They will all teach me something useful. I am an engineering student and just want to learn more about this tech and make my own. Please keep your negative comments to yourself unless you have something constructive to add next time. I will do the same in my future posts. I will, however, consider looking for an old computer at a garage sale.

PurduePete

Sent from my iPhone

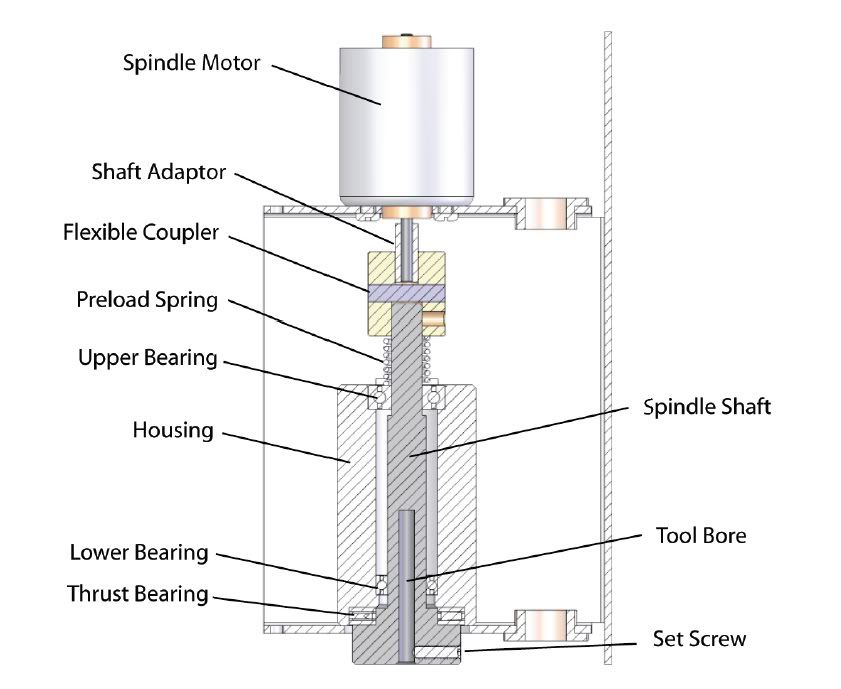

I did want to share this design that I found. I am going to attempt to reproduce it with a few modification. Currently I work in a machine shop on campus (one reason I'd like to learn more about CNC) so most of the parts can be made there as I can use the lathe. The most interesting and frankly awesome idea that was in the whole paper was the spindle. The MIT Engineering student designed a spindle using a $2 hair dryer motor and a fairly interesting coupling system. He is able to get speeds of 15,000 rpms. The whole point of this machine is PCB milling which for now is what I want. Later I am going to use some massive stepper motors that I will have and build a really cool CNC.

Here is the link to the thesis paper with lots of photos and excellent descriptions. He goes into some physics about his setup for moving the axis but it is not too complicated. The rest of the paper I found very easy to read. Here is also a picture of the spindle setup that he uses.

This may not be interesting to you guys as it is not super powerful and not huge but it was fascinating for me. The machines on this website are fairly large and generally use the same types of technology, this one seemed to use a few different ideas that were new to me. Obviously the spindle is the most interesting to me and probably a model I will adapt to my own design.

Last edited by PurduePete; 07-20-2012 at 12:56 AM. Reason: New Information to Share

Not sure what you mean for the serial port; most stuff I have seen is driven by the parallel port, not the serial port (unless it is something related to doing PC boards).

The thing is, the most mature stuff out there is parallel port based. You can find things that are USB-based, but most everything was driven by the parallel port for the longest time, so you will find the largest assortment/variety if you go that route.

As for a machine, you are better off having a dedicated machine on your CNC machine. That way, you are not twiddling your thumbs wishing you could get online while you machine cuts a 2 hour, 3 hour, or longer job. You can drive a CNC machine with a Pentium 4 desktop, and many people will just GIVE those away (at least, that has been my experience...)

I meant a parallel port, not serial. Just a mistype. Sorry about the confusion.

I am discovering the same thing, a parallel port board is probably the way to go. As for machines I have 3 laptops and a monster gaming computer (built that for my girlfriend so don't want to use it). An extra computer isn't the issue, but the parallel port is. My dad says he might have one that hasn't been used in years that I could take if I can fix the hard drive. Happen to have an extra laying around that just needs to be formatted and Ubuntu for the Linux CNC dropped on it.

I did have a question about the 2 or 3 hour jobs. Can you not minimize it and check e-mails or anything? Like I said it won't matter, just curious as I have never done this kind of thing before.

I think for about 20 bucks you can buy a PCI card that has the Parallel port you need.

Some people even advocate not having your controller PC on the network at all, just sneaker net files to it for processing...

Well I went ahead and bought a mother computer for this project. Purdue has has a salvage store and was selling about 12 computers for $20 ea. I bought one, they all needed a drive but I had one laying around. Has 4gb. of ram and a 3.2Ghz. processor. Already installed Linux hardy heron 8.04 and it runs well. Now it is time to build the controller and set see about doing some testing. Thanks guys.

PurduePete

Sent from my iPhone

Another Boilermaker here! Hope you have had time to get your machine built and running. On computer note, I am using an old Compaq laptop my daughter had years ago in high school -- actually a replacement as the original died so I found another just like it on ebay for $29 (and it looked like it had never been used), popped the hard drive in and off it went running WinXP/Mach3 out the parallel port to a HobbyCNC controller. A very basic minimal ancient machine at this point but it works fine, so that might be something to consider in the future to minimize the size of your setup.