eaglezsoar,

To be fair and honest, if Mach3 and the LPT is doing everything you want it to, there is likely no good reason to migrate to the KFlop. If, however, you want to use USB from a laptop, a PC that does not have an LPT port, are having trouble with Mach3, or want better performance from your steppers, then the KFlop solves those problems. Additionally, if you are just starting out and have not purchased Mach3 then the cost of the KFlop with KMotionCNC is within $75 of Mach3 alone, making the KFlop an "easy choice" as far as I am concerned.

jasminder,

As stated above, if you have an existing system performing satisfactorily the KFlop may not be a good choice for you. If you are having problems with an existing system, or are building a new system then the KFlop has a lot to offer in flexibility, performance and stability. As far as configuring the KFlop using the KMotion App, yes, it can be a bit scary, but hopefully I will have a front-end ready for use for simple open loop stepper systems in the next week or two that will make the task considerably easier.

Gerry,

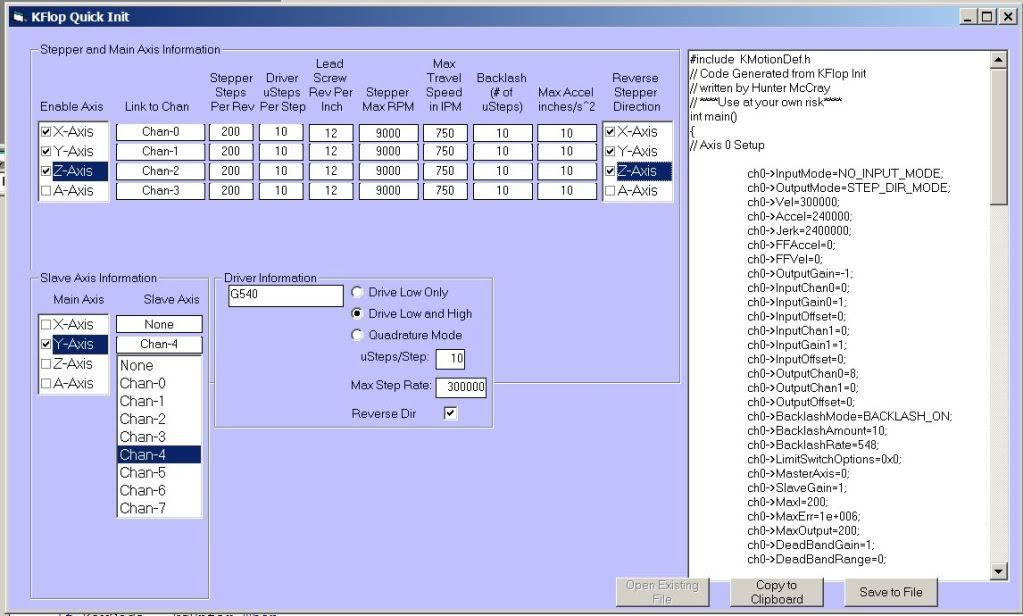

I have revamped the way my front-end works wrt Axis/Chan/Master/Slave, here is a screen shot:

Honestly all of the fancy gui stuff only really changes a couple of lines of the configuration script, but hopefully the gui will make those changes more intuitive to users.

Fish

Reply with Quote

Reply with Quote