Wow, I first read through this thread about four months ago while searching for information on building an MDF router table. Since then I have completed my 5x9 MDF table, which is based on Patricks Blacktoe design. I did not purchase his kit. This was not because I believed that it was not worth it nor did I believe that MDF is not a good building material (I am a custom cabinet shop owner, I know better) but because I love to tinker and build. It was as much fun designing and scrounging my own materials as it was putting them together. Having read through the thread again, including the latest posts added after my last visit, I wanted to share my experiences with MDF and a BlackToe knockoff.

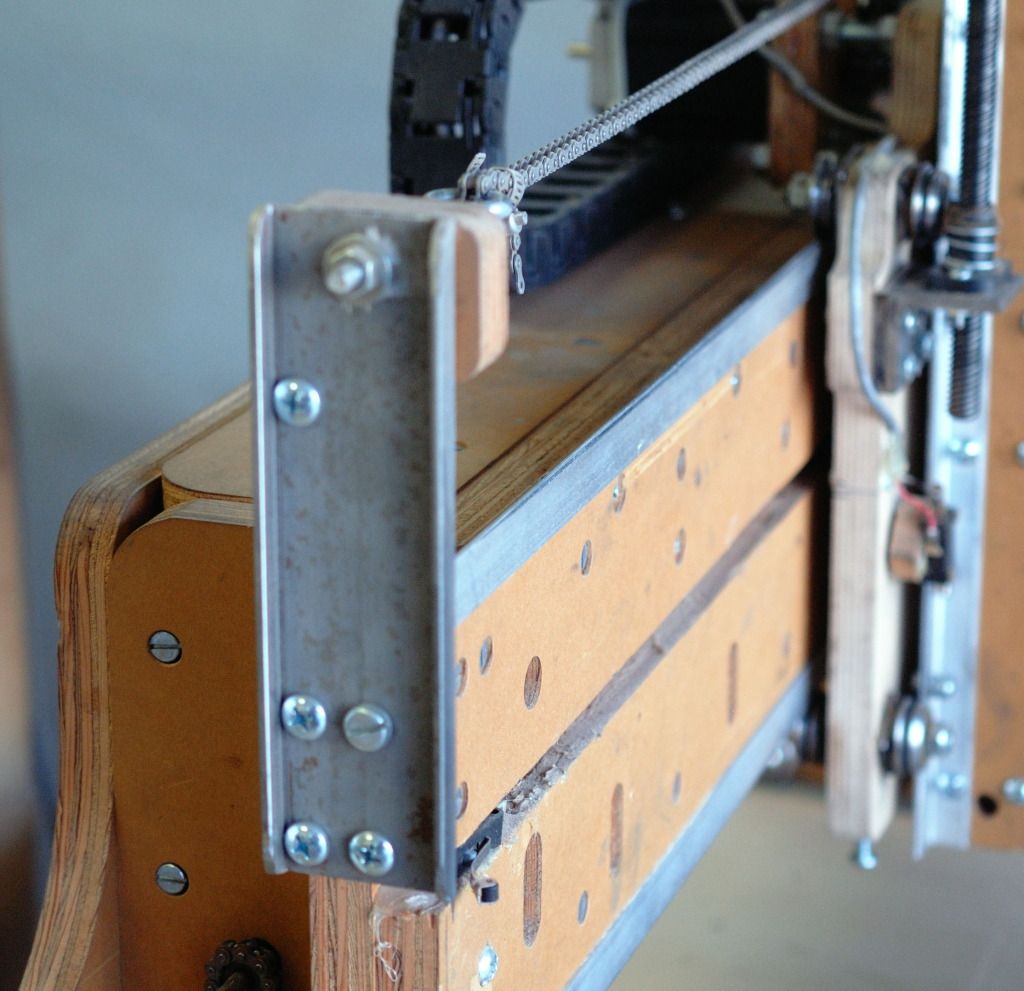

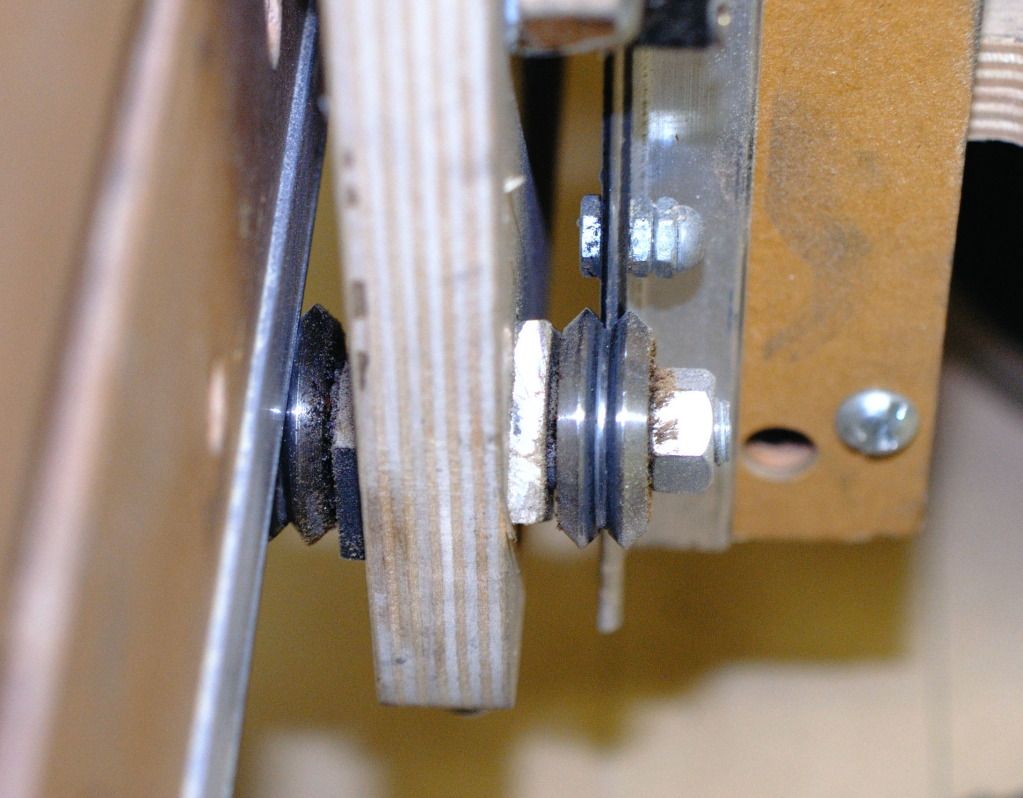

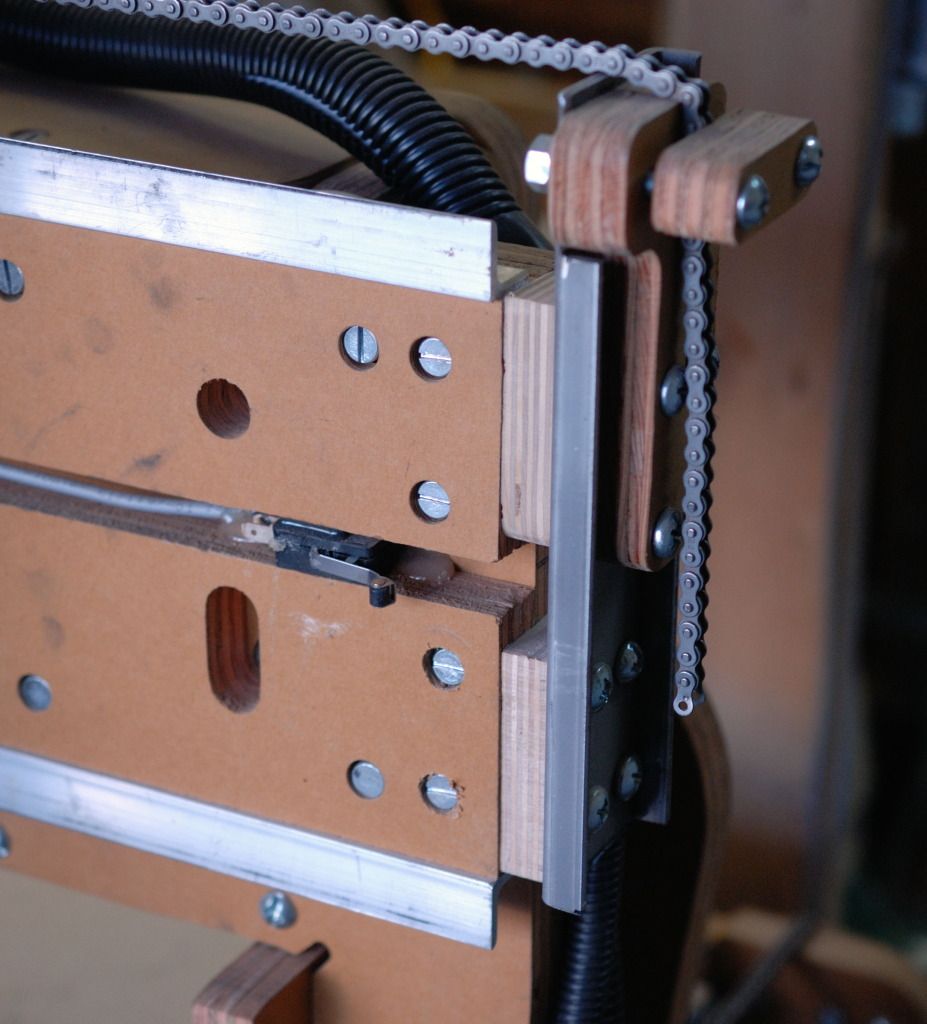

My table is not bolted together, the gantry is glued and screwed (holes are bored and countersunk). The v-bearings are bolted using overlarge washers so they do not damage the MDF and so allow adjustment as needed (after the v-bearings wear the L-channel to seat properly I needed to readjust but they have not needed another adjustment in several months).

I have done several tests (a couple purely by accident) to see how accurate and precise my machine is;

1. Mach3 has an included G-code file called Roadrunner, I am sure most Mach3 users are familiar with it. I built a pen attachment for my CNC system, laid a sheet of birch ply on the table and had the machine draw out the roadrunner. I then lifted the z moved both x and y (without resetting any one of them to zero) and restarted the process. At no point did the pen leave the path of the previous drawing. Interesting.....soo...

2. Using the Mach3 manual, I learned how to send the pen to certain points on my table by manually entering the xyz coordinates. I would then move the head to a random point and have it go to those coordinates again....spot on every time. The pen left a mark one on top of the other....for me this was pretty amazing as I did not expect the precision nor accuracy that I was witnessing.

3. The other day I was running a complex job involving a celtic braid (looks like lots of worms to me but a customer wanted it). I lost power half way through the process (my fault, I put the entire table and my edge sander on the same circuit but that has been fixed now). I had to restart the machine, computer, and process. I re-zero'd everything (lucky for me I had gone slightly into the material with the tip of the engraving tool so I knew were zero was for this job) and restarted it from the begining. A perfect job, the first half was exactly like the second half even though the tool passed through it twice.

I would like to address some of the issues with MDF;

1. I live in West Michigan, as many who have visited here in the summer know; we get 90% humity as a matter of course. MDF does not "Swell up" in high humidity unless it is left outside in the elements and the occasional rainfall in that case would do more damage than the humidity would. If it did, we would not use it as a building material for cabinetry.

2. MDF is not as strong as metal, very true. But it will not fall apart nor "wobble out" any more than metal will if it is properly built. Loose bolts in vibrating aluminum will result in wobbled out holes, not at as quick as MDF (true) but the end result will be the same. Several years ago I decided to build a larger edge sander (80") for the shop. Usually I would have just purchased a Jet, Powermatic, or Shopfox (well, maybe not a shopfox :> ) but I found plans for an MDF machine that looked intriging (Shopnotes magazine). I have been using that sander in a production shop for almost ten years with no maintainance needed so far (yes, I do change the belt on occasion). If vibration were to cause a failure of the MDF, that machine would have fallen apart long ago.

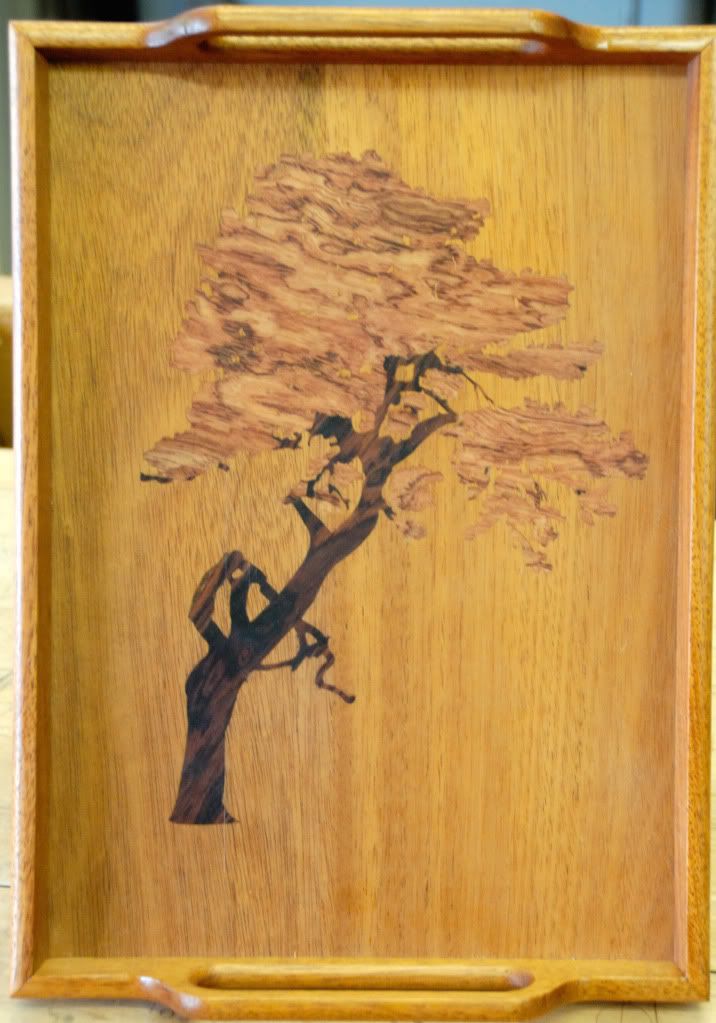

I built my table using standard shop tools. I then used the resulting machine to cut out the parts for my "Upgrades" (mostly for estetics but I wanted to raise the height of the cut so I could experiment with larger 3D projects).

My machine goes where I tell it to (even if the place I tell it to is the wrong place, lol) and does what I tell it ito (see previous comment). I am very happy with the MDF machine and am sure it will last for many years, I base this on 16 years experience with MDF.

By the way, I have done some "hobby" stuff on Aluminum and Brass (I build custom steampunk PC cases and Sim Cockpits). I have not found the machine to be any less precise or accurate cutting those metals. I will admit that I have no plans to cut steel with the machine, although if I built a Jig to hold material and catch coolant I am sure I could do so (perhaps a low sided tub that bolts, externally, onto my table...hmm....)

Total cost to build my table: 1293.00. This includes an old PC (P4) from Ebay, Mach3 software, and all hardware. Vectric was another story...sheesh! (but worth it)

MarkII:

Reply with Quote

Reply with Quote