Maybe wobble isn't the right term. More just to jolt and I can see movement.

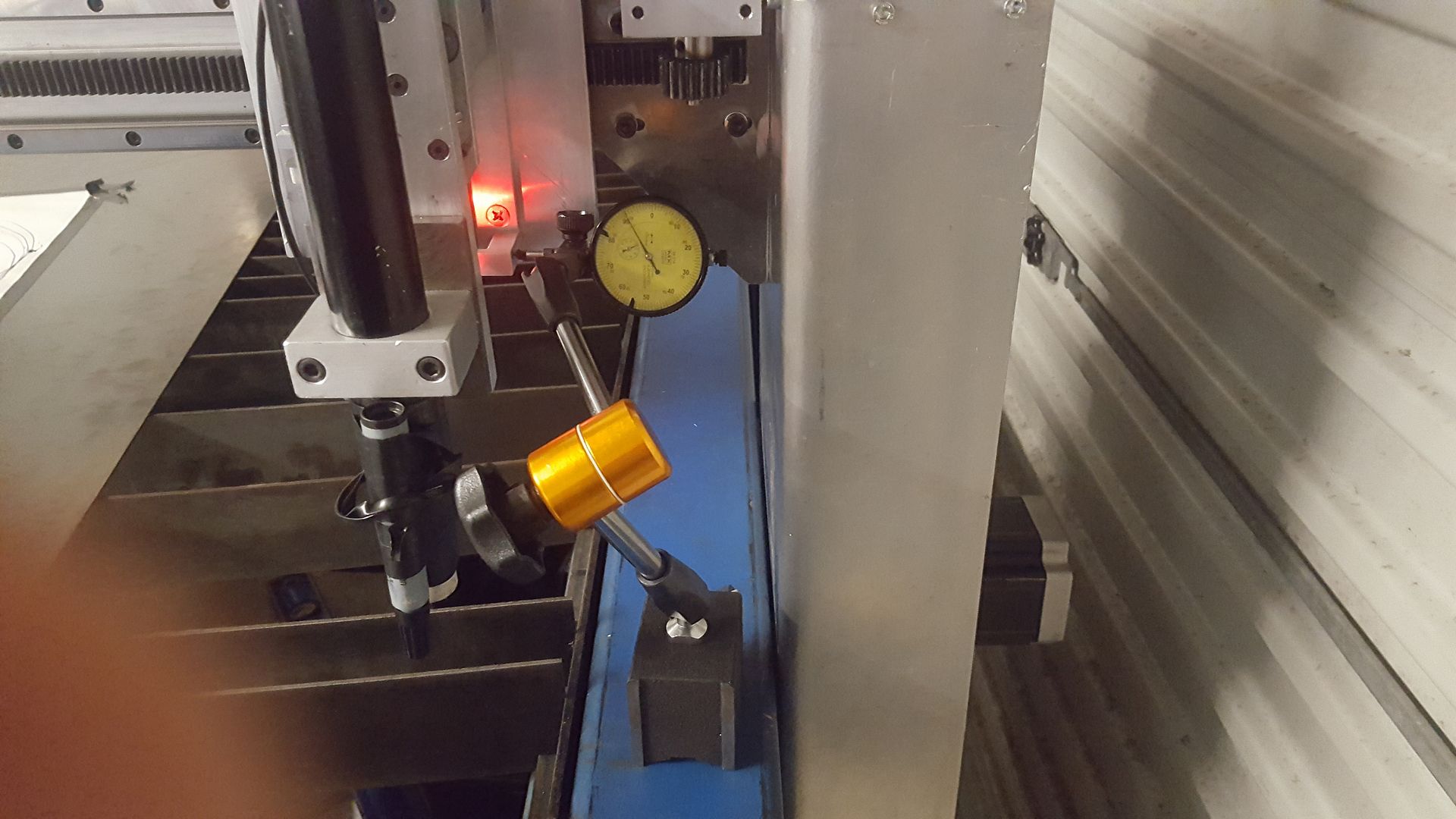

I'm also not super impressed with the linear bearings. a couple have very slight movement. Nothing I can see or measure but I can feel it when I put force on the bearing in various directions.

Reply with Quote

Reply with Quote