Nice job. Like the use of an old PC case for the PS and controllers. I am doing the same thing.

Do you have a schematic of your PS?

Hager

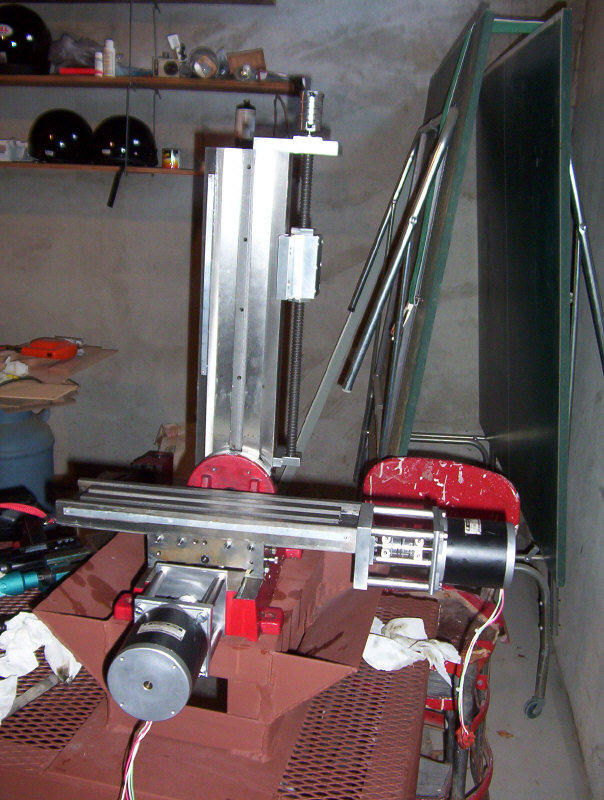

Hey guys, Im in the process of converting my mill, Im almost complete actually.

What I have is:

Homier mini mill

Gecko 201s

Japan Servo KP86SM2-002 Stepping Motor

2.35 VDC, 1.8 Degrees/Step

They are bipolar 2.5V @ 4.1 Amps

A power supply I made:

24v(12-0-12) transformer(1 or 2) 80v max 18,000uF capacitor, and bridge rectifiers.

At 24v I get around 30v after capacitated, at 36v I get 56v max after capacitor, Im affraid of even hooking up total 48v to it because my cap may 'splode. I really wanted to run these at 48v but Ill have to get another capacitor with a higher maximum and a voltage regulator.

So right now I have the 24v hooked up because 56v is close to the absolute maximum of my motors.

The motors are rated at 4.1A but I was told to run them at 2A because thats not over 67% of the rating. Should I have it at 3 or even 4amps?(set on my gecko 201s)

Heres some pictures of where Im at:

http://www.wc101.com/JFettig/mill/

Heres a short video, dont download it too many times, I might be short on bandwith.

http://jfettig.wc101.com/cncncbig.avi

*note* Yes I realize the Y is backwards

Also I have a pully set I got made up, maximum of 9000rpm, I took the bottom bearing and spindle out of the head, and didnt have a flange to take the top bearing out without killing it, and to put it all back together I'll need to get ahold of a boaring bar and make some when I get my lathe unless someone else has another idea or could help me out with that.

Let me knwo what I should do,

Thanx

Jon

Similar Threads:

Last edited by cncadmin; 04-01-2004 at 12:24 PM.

Nice job. Like the use of an old PC case for the PS and controllers. I am doing the same thing.

Do you have a schematic of your PS?

Hager

Nice; did you get the steppers from Toronto surplus? I just ordered 3; have you chked the power of those steppers; I asked for the torque rating and she did not have anything to offer

BTW; love the vid

Heres a scematic. The voltages are what they should be, but Im getting 16v out of the 12v, 30v out of 24v, 56v out of 36, and it would be around 70+v out of the 48v.

http://www.wc101.com/JFettig/mill/PSscematic1.jpg

I just used my electronics knowledge to make it without drawing a scematic, but I just drew this one for people who are interested.

I actually ordered those steppers off of ebay, then a few days later I saw them at toronto! for cheaper!

I do not know the power, I would guess its 300+oz because its about the same if not more than the vexta 305s I beleve if I remember right.

-edit-

Can anyone tell me any info on the amperage? I want to know if I should be running them at 2, 3, or 4 amps.

I fixed the pic, I had the outputs wrong

Thanx

Jon

Last edited by cncadmin; 04-01-2004 at 12:26 PM.

I'm still in the planning stages for my fully built by me 3 axis cnc mill

But with $35 price tag i couldn't resist

I'll also get the servos that are listed for 9.95; but I'll have to add the US digital encoders

I want to try both setups

Im still waiting for my metal, onlinemetals didnt ship it for some reason, I got almost everything but that and another peice

I still need information on volts and amps of what I shoudl be running.

Thanx

Jon

Hi Jon,

I have the KP86 steppers too, and I'm in the same situation as you are: Should I run at 2 or 4 amps? I have tried running one motor at 4 amps with my G201, and it didn't get too warm, but it was free running. I haven't tried any weights or anything to check the torque. If I could get away with 2 amps, then I can use my old 8A power supply and not have to buy the parts to build a "monster". I would like to keep enough torque to make these steppers worthwhile, though.

BTW, I'm using these to replace the old unipolar steppers/FET3 on my HF micro mill, hoping they would give me a little more speed than the 5"/min that I was getting before with my 125oz motors... I'll be watching this thread to see if someone else has worked with these motors and knows about the required current.

Billy

I dont know what kind of speed you will get with leadscrews, but with ballscrews I can get up over 60ipm I beleve. Im not 100% sure, Ill have to hook it up to my main pc with mach2 to see if itll read out for me. I can definately go well over 10 thoughand thats at 24v(around 30v)

Jon

my Japan Servo KP86SM2-002 Stepping Motor's arrived today; I thought they might be used take-offs; but no NIB's for sure; still in the man/ers box; great deal for sure

I've already updated my CAD drawing of the mill to NEMA34 sized drives; now a question; can anyone here tell me how to hook these up to a manual driver; i want to drive them like a manual jog on a full sized CNC Mill; it would be nice to have a multi switch to change the step increments; say 0.01 then 0.001 and finally 0.0001

stevie, you can jog the motors using a program called TurboCNC. It has a jog screen that will allow you to do exactly what you want.

Also, let us know the OZ-in of those motors. It seems to me that they are more around 80 to 100 oz-in. but I am just guessing by comparing them to others on the Japan Servo website.

T

I think they might be bigger than that; here's a link to the size I've got http://www.microkinetics.com/34m315.htm

sorry; edit; forgot to add; the lathe I want to jog them with is going to be fully manual for a while; I just want to speed the main carrage down the bed with a stepper

The mill project I need a similar set-up; but this will be for pick-up; I really don't want a PC in my garage; so I want to make the cnc mill use floopies and I'll tool path in the house

A laptop would do ya good, thats what I am using, a p166 compaq.

I really would like to get some information on the current I should be putting through these motors.

Also, does anyone know of a good way to make some decent ballscrew covers? I need one for my z axis.

Jon

https://www.reidtool.com/store/store...dCategory=9028

Here are baLL screw covers

Yeah, I was hoping to make my own, I dont have $30 a foot

Jon

That is very exspensive for sure.

Thank You,

Paul G

Check out-

[URL="http://www.signs101.com"]www.signs101.com[/URL]

I got it all up and running today, I still need to make new pullies for the spindle drive so it has more torque, I am able to cut aluminum pretty well, I tried copper and it locked and snapped my 3/32" em pretty fast. (the motor protection thinger stopped it) I was cutting some with a 1/2" end mill, shallow cuts, no problem, Cut a little delrin, that went really well. Got part of my steam engine made.

Im working on the main body now, and the flywheel

Jon

Need pictures!!!

Thank You,

Paul G

Check out-

[URL="http://www.signs101.com"]www.signs101.com[/URL]

Alrighty

Http://jfettig.wc101.com/cnc.jpg

one of my first parts:

Http://jfettig.wc101.com/keychain.jpg

a part I just whipped out

Http://jfettig.wc101.com/crank.jpg

its for my steam engine Im workin on. I already got the piston made and I made the cylinder earlier today.

Heres a pic of it between cuts in the cylinder(delrin) I made a shroud around the table that attaches to the X axis, thats a temp one, Im going to make a really nice one soon. itll be ready for flood coolant

Http://jfettig.wc101.com/cnc1.jpg

Jon