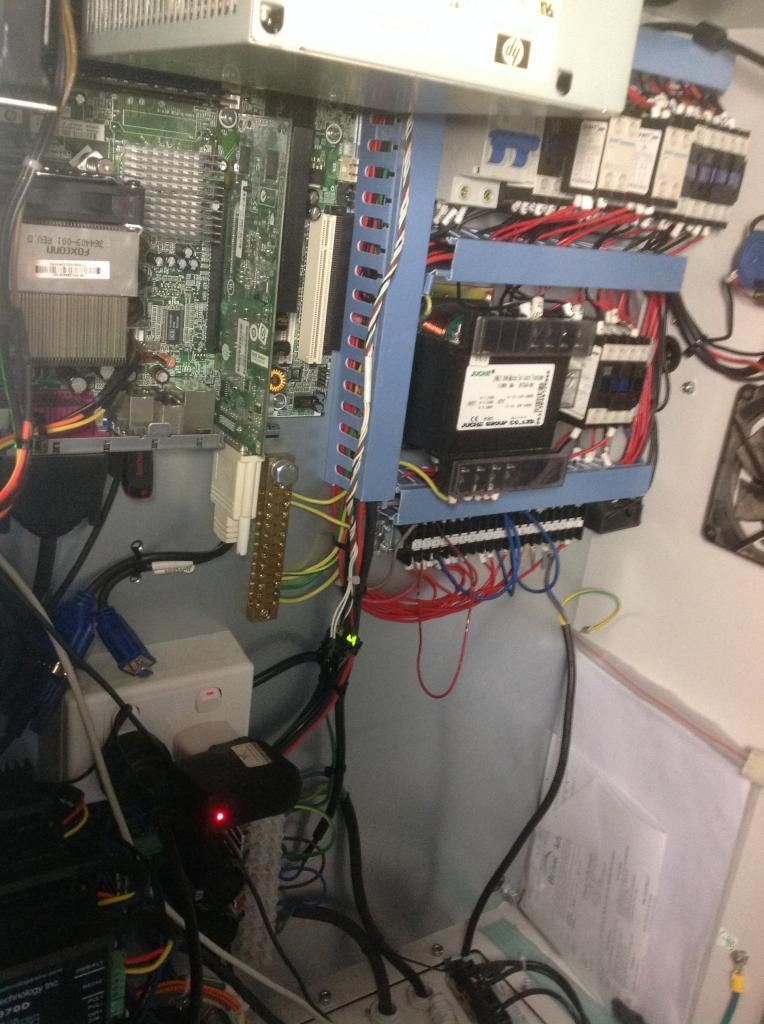

my Enclosure has shown up, local B&R Rep helped me out considerably, Ive made the brackets to bolt it to the machine, the box is 800mmx600mm, which allows enough room, to fit all the electrics for cnc, the power supply s, contactors, drivers, and room for a VFD for later down the track, Ive got it all blasted and painted it today ready to put together tomorrow.

Reply with Quote

Reply with Quote