Originally Posted by

charliex

Hi Kenny,

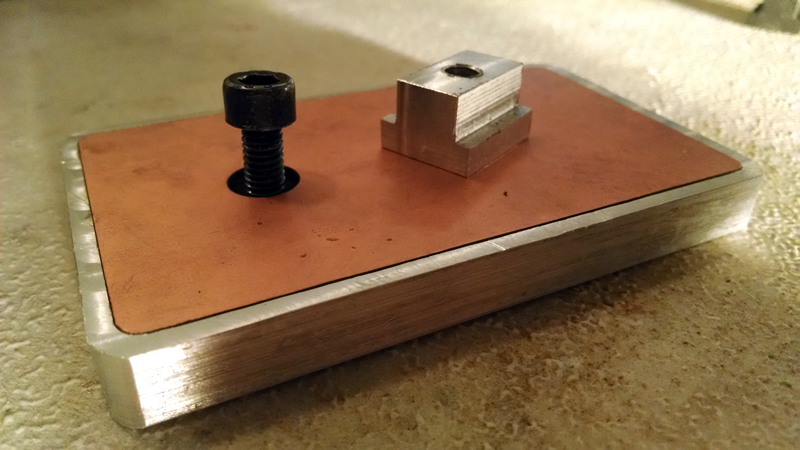

Yep i've changed the spring to the medium and its running a test at the moment, the cable out the bottom hasn't been a problem, it's just a preference. I did notice its easy to knock the probe off the spheres it sits on, also just as easy to put it back. its a nicely made probe.

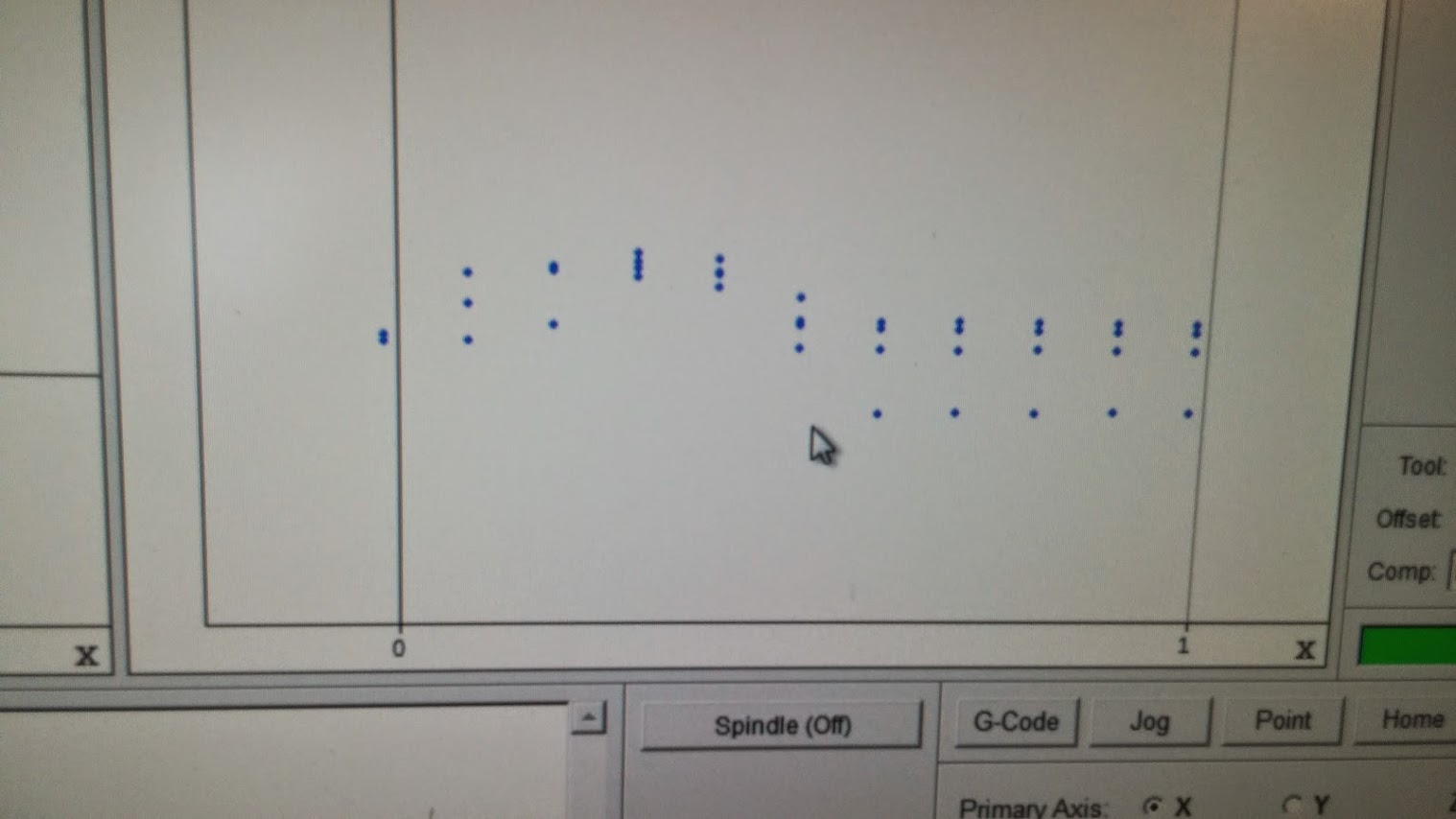

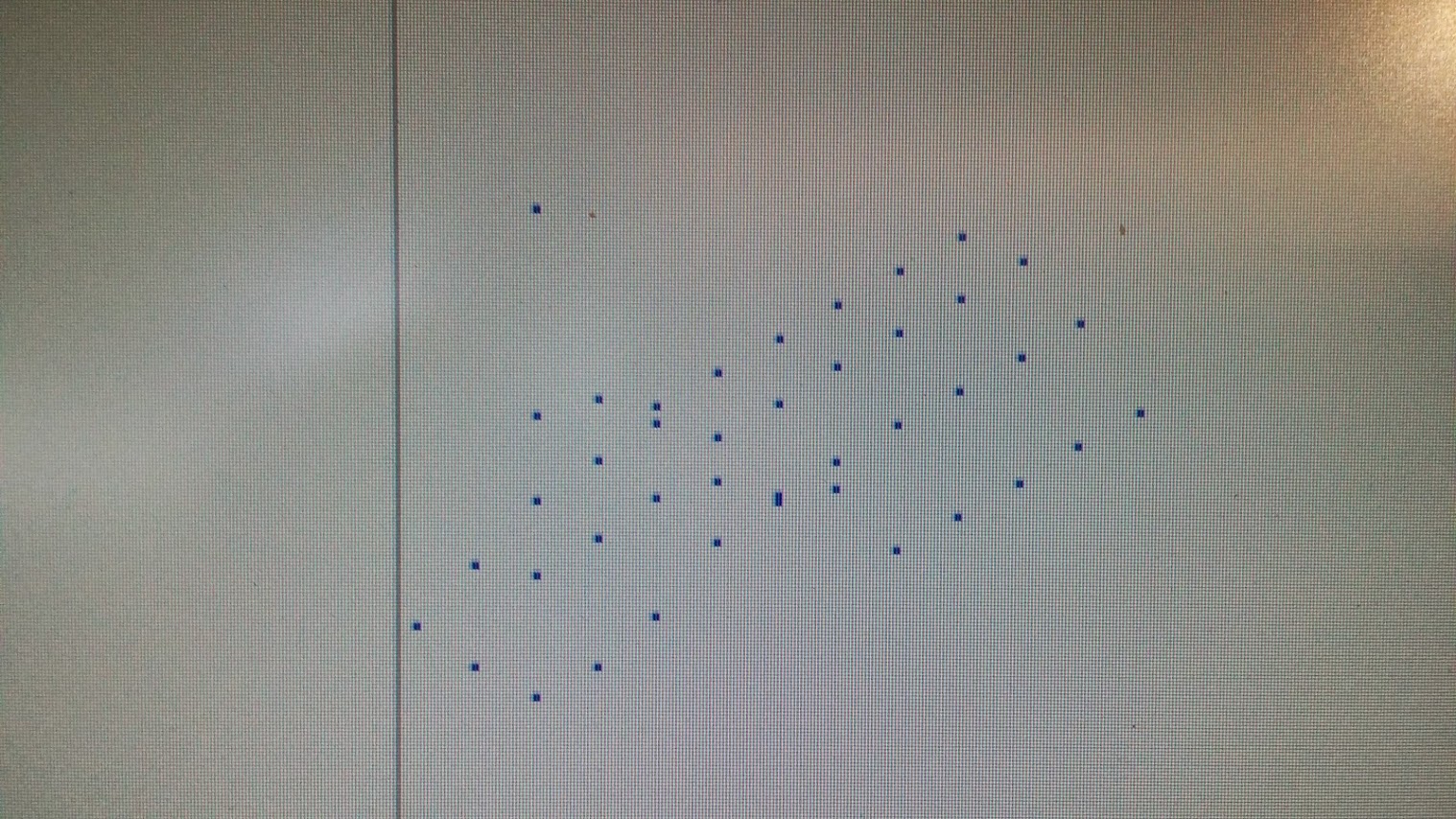

I have a wierd thing where flashcut just stops for no apparent reason, i can continue the job but it'll just stop as if the feed hold has been pressed, i emailed the tech support guy, see if they have any ideas.

Reply with Quote

Reply with Quote