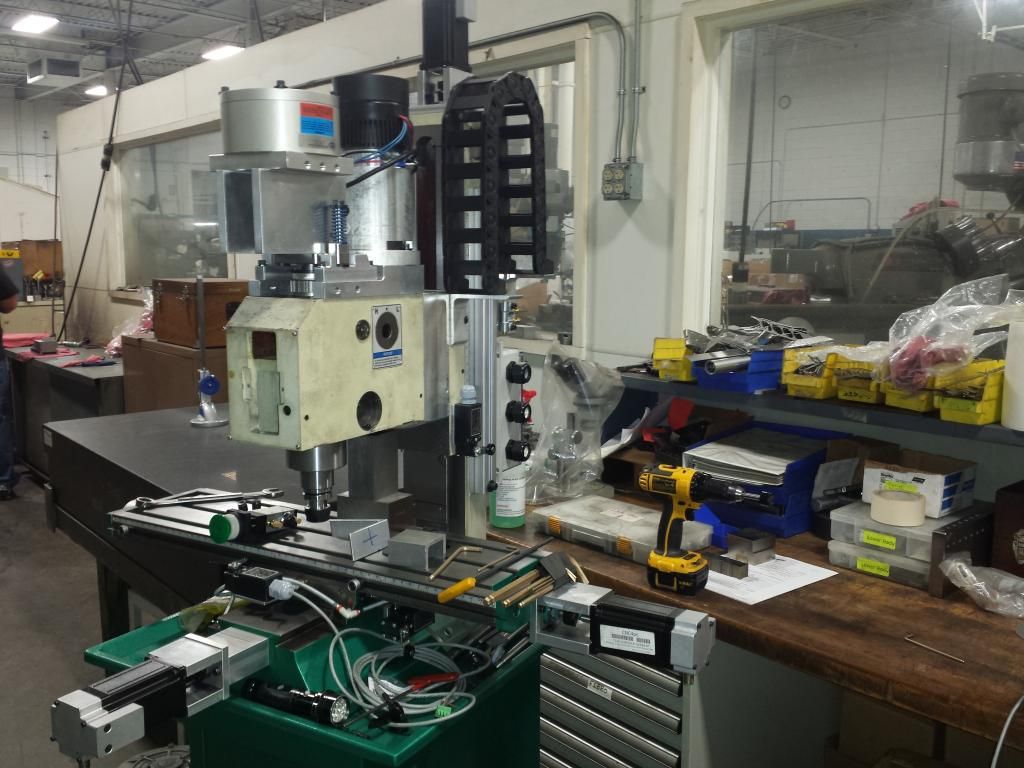

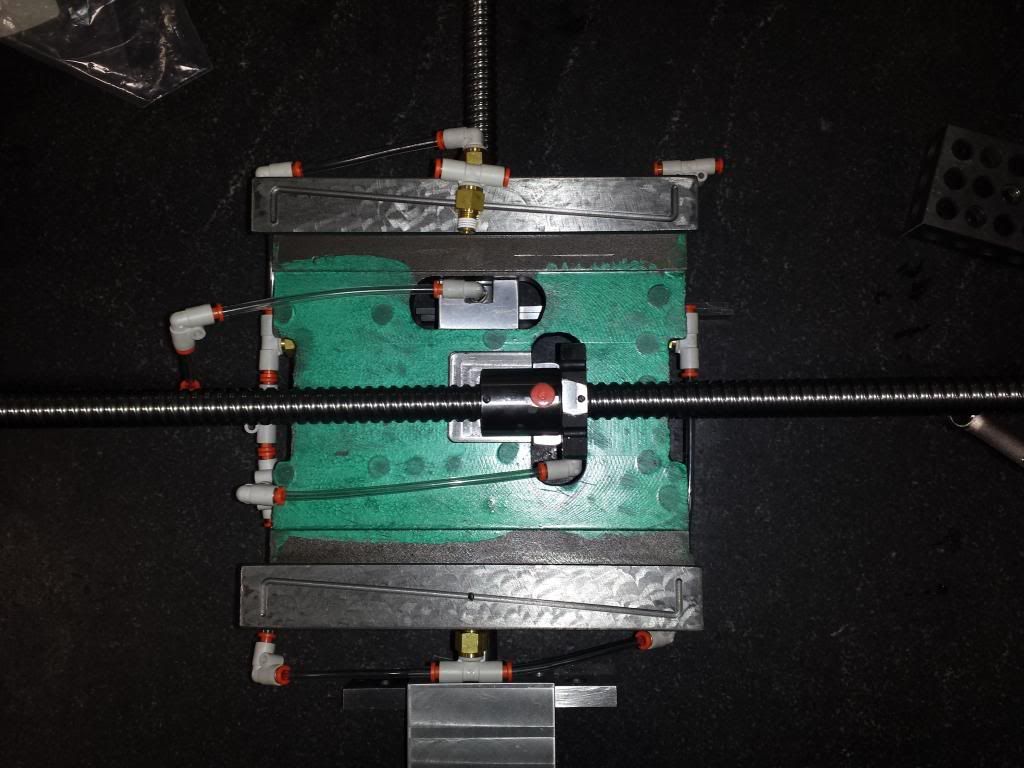

The fitting on the near side was not installed yet in that pic. I ran out of fittings as this was like the third time I had changed the way I was oiling the saddle. you can see the one valve on the junction bar that is missing its hose. the oiling point is blocked by the ball screw.

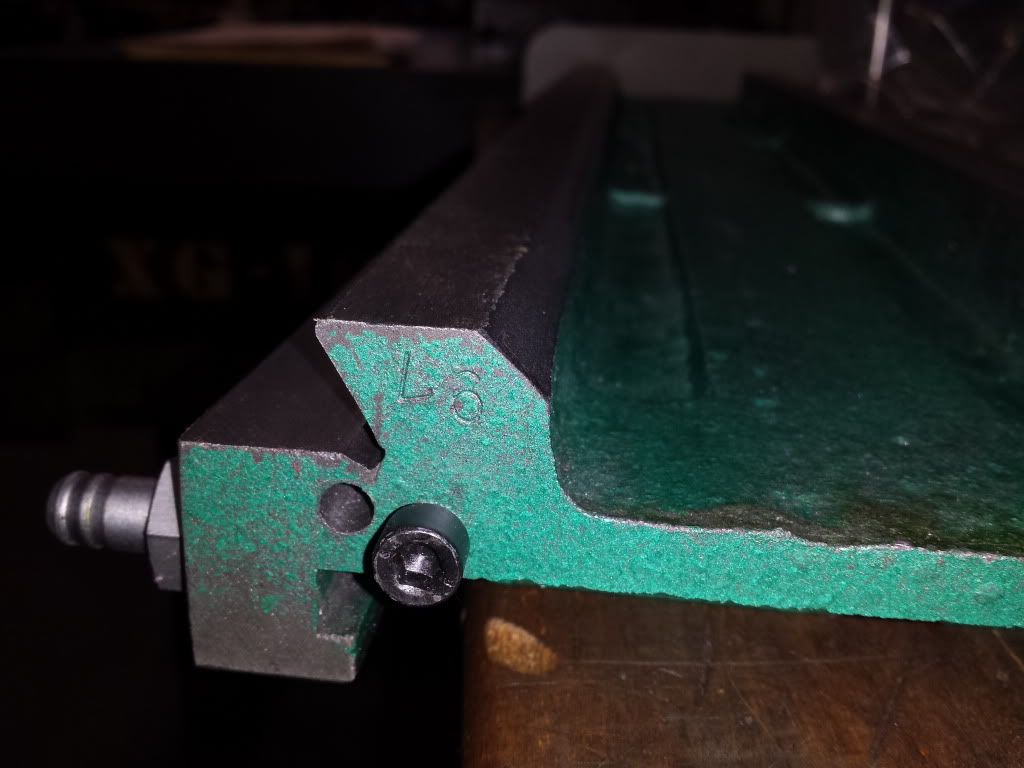

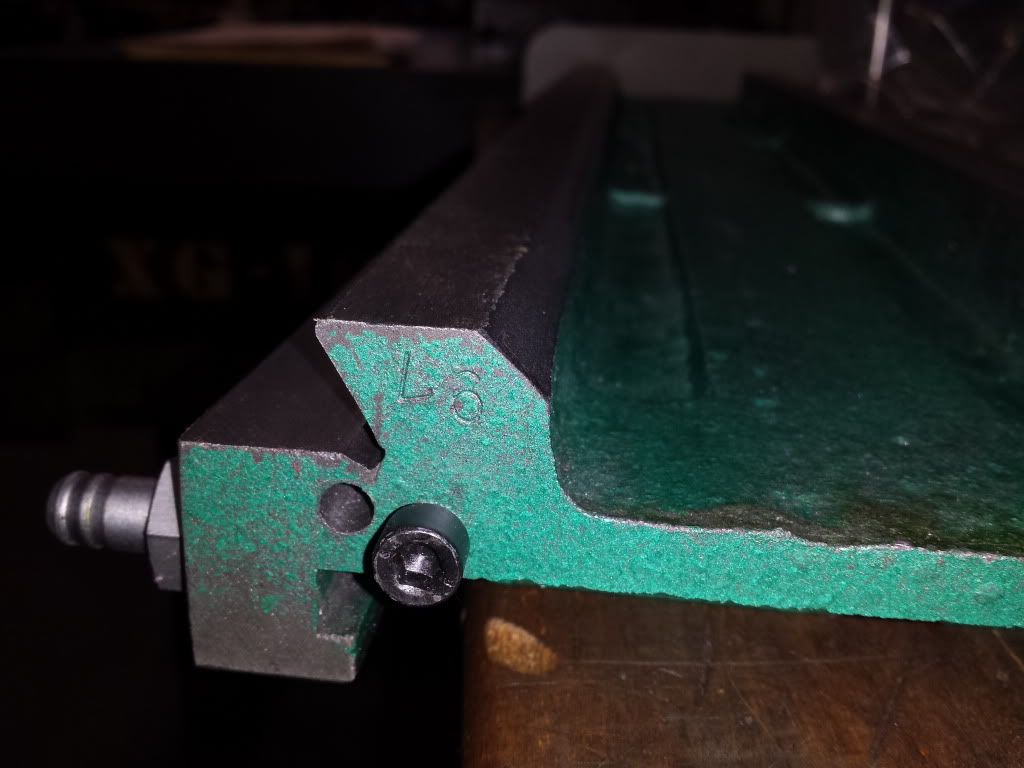

I'm not sure which fitting I would use for the Y ball nut. the 90 degree adapter or the straight hose adapter and banjo assembly. On my mill I milled a 45 degree on the rear dove tale to clear fitting.

I you flip the Y ballnut mount to the other side you might have enough clearance? wish I would have thought of that before

.

For the X ballnut I would use the 90 elbow and mill (grind) clearance into the saddle for the fitting.

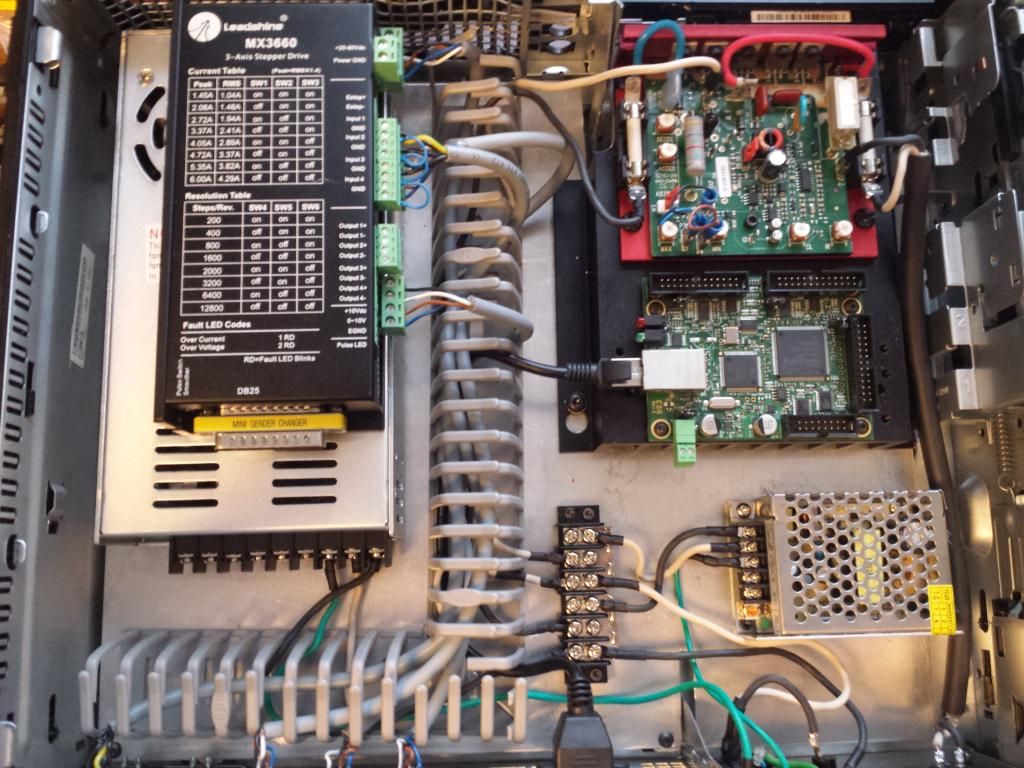

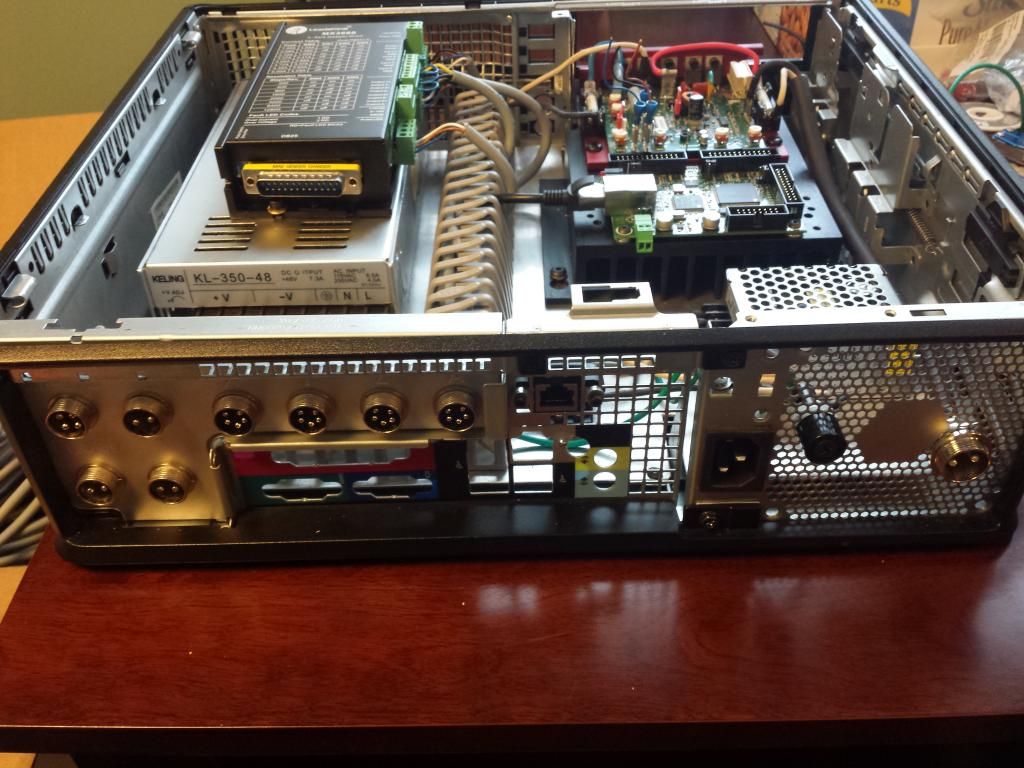

The Z was a tight fit as well. I had to round off the corner of the fitting to clear the corner of the column.I also have the oil line come in at the top where the hand crank was and loop down and back up on the inside of the casting. Not sure how this will work in the long run, but it did survive the 100 travel back and forth program I ran while testing the ESS.

Also if you order from arc euro trade, there is some weird thing about staying under 100 euros. if you go over it becomes some hassle playing phone tag or something because its and over seas order????

Let me know if you need anymore info,

Andrew

.

.

Reply with Quote

Reply with Quote

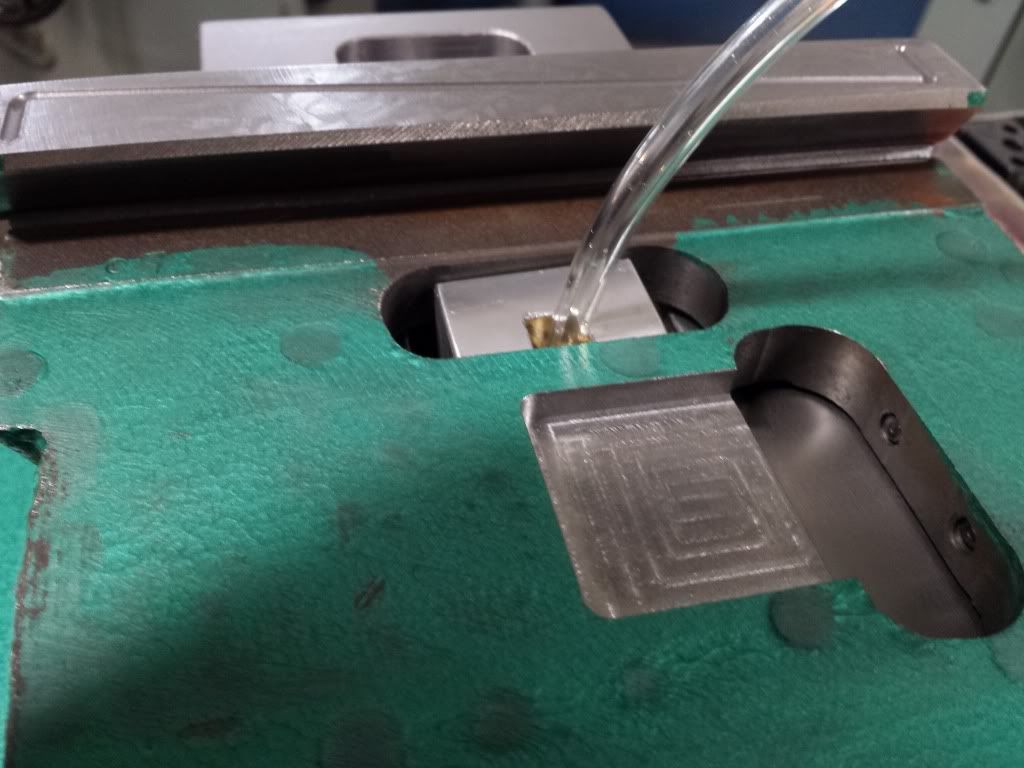

) The ball nut MOUNT is drilled and tapped for the oil fitting. It basically drips oil onto the ballscrew thread, not directly into the ballnut.

) The ball nut MOUNT is drilled and tapped for the oil fitting. It basically drips oil onto the ballscrew thread, not directly into the ballnut.