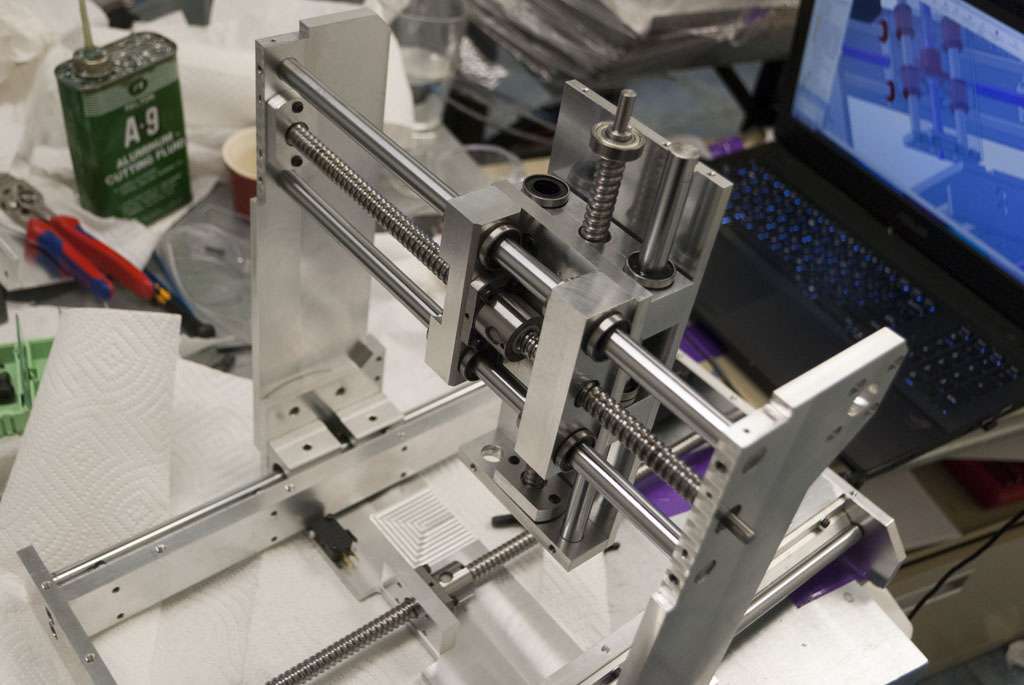

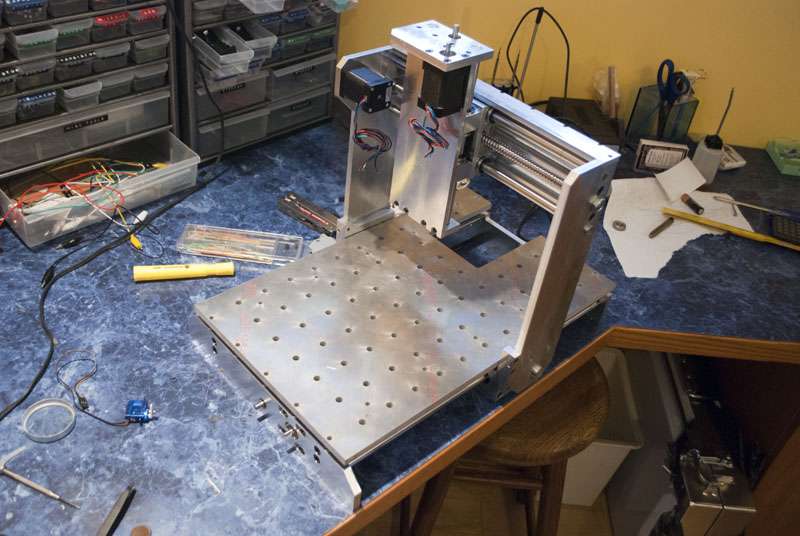

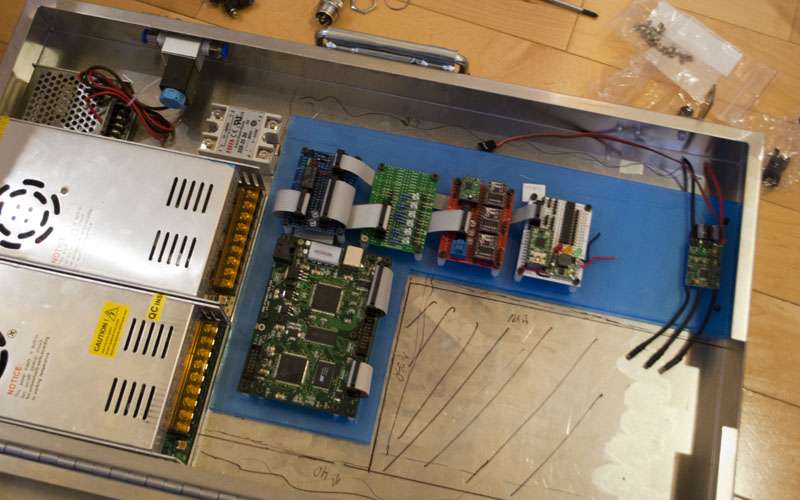

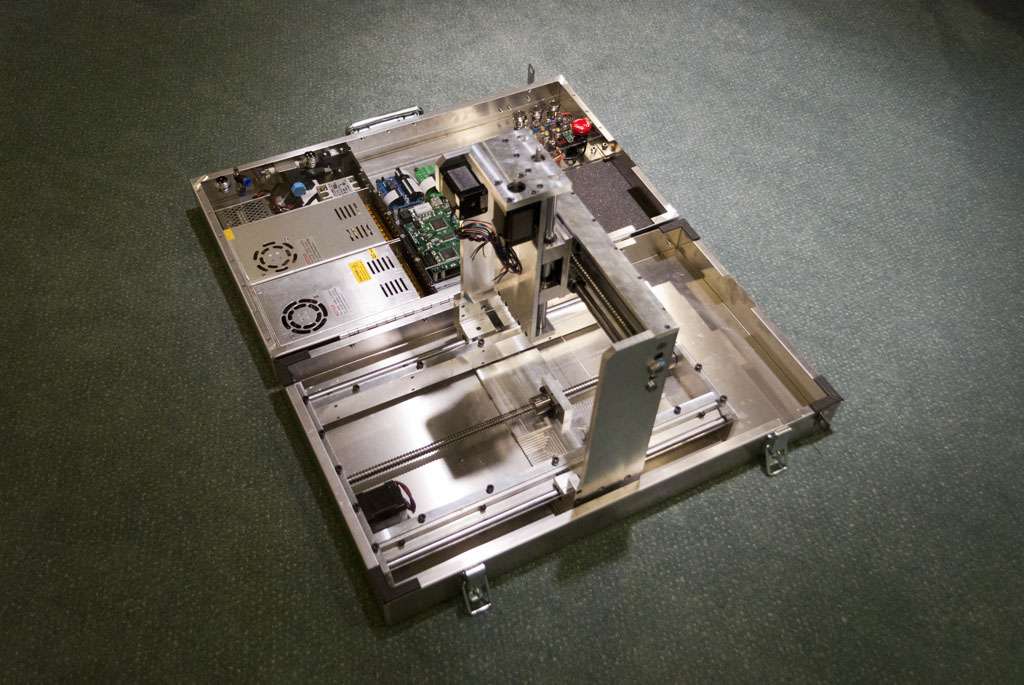

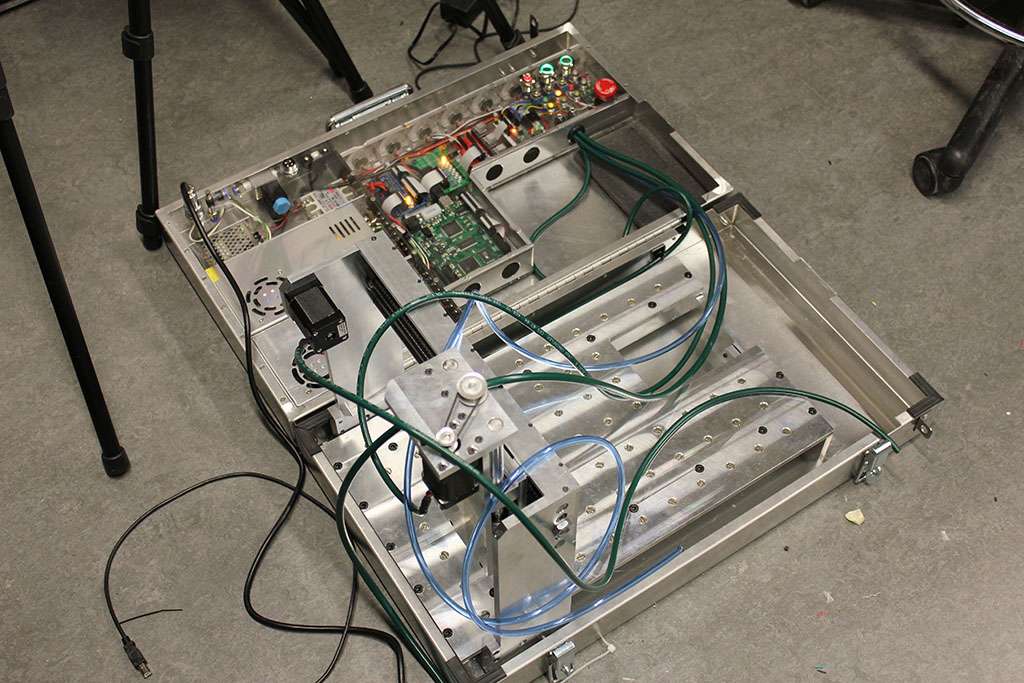

The router build looks like another fantastic creation from you and reading your analysis of the KFlop stuff earlier.....well....alas that stuff went straight over my little mind...but again I must say WOW this cnc'd mill build is one freaking excellent build...I'm going to follow you and others and lap my ways....and again Ryan thanks for the explanations and pics..

This build is definitely one of the best builds I've seen well done...and keep the pics flowing for those of us (ME) who find it easier to learn from photos rather than learning from reading ye''re progress. ..

Reply with Quote

Reply with Quote