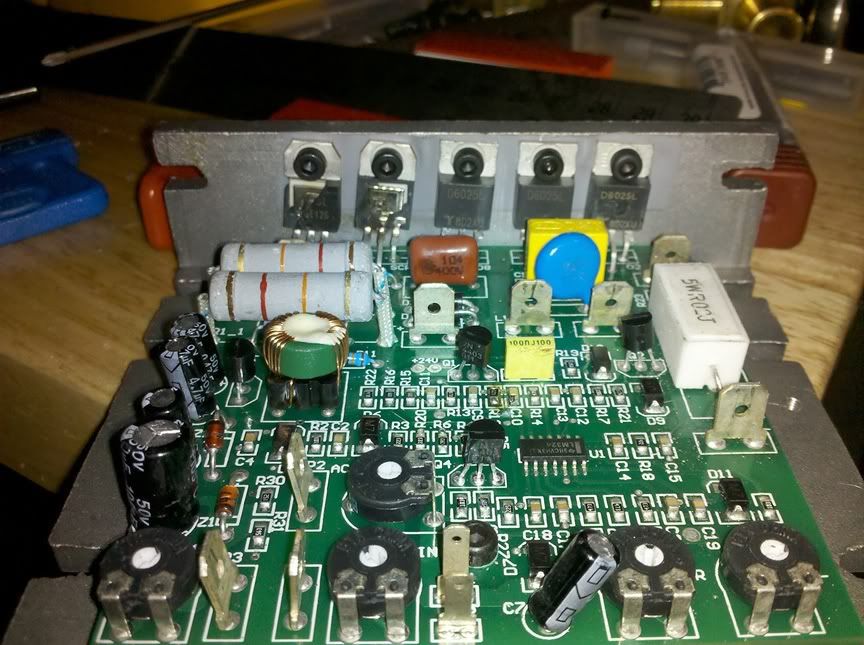

You should be able to get the original Teccor parts or equivalent, those two are the SCR section of the bridge, it would pay to test or just replace the rectifier pair as well.

It pays on those small SCR bridge drives to bolt a good piece of aluminum to the the rear, in fact Baldor and KB, who make the equivalent drive recommend it.

Al.

Reply with Quote

Reply with Quote